3D Plastic Printer Tips for Beginners and Pros alike?

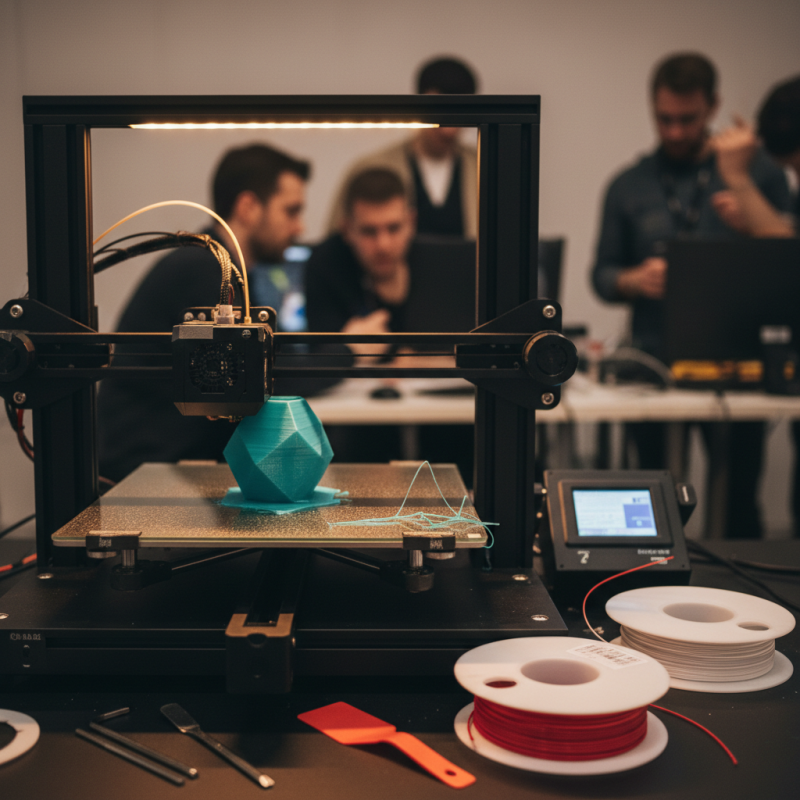

The world of 3D printing is both thrilling and challenging. For those new to the 3D plastic printer, it can feel overwhelming. You might struggle with settings, materials, or just getting started. Yet, there is a community ready to help. Resources abound, but knowing where to find good advice is vital.

Experienced users also face hurdles. A 3D plastic printer can behave unexpectedly, and even small details matter. Balancing speed with quality can be tricky. Many find themselves going through multiple prints to achieve a perfect result. More often than not, the need to refine techniques leads to relentless experimentation.

Mistakes happen, even with the pros. You might overlook bed leveling or forget to check filament quality. Learning from these setbacks is crucial. Embracing the journey of trial and error fuels both skill and creativity in 3D printing. Whether you're a beginner or seasoned user, valuable insights await you.

Table of Contents

[Hide]

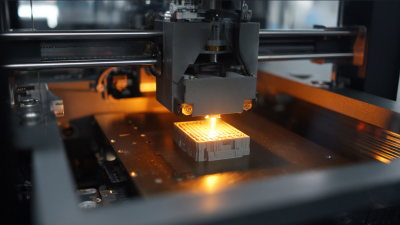

Understanding the Basics of 3D Printing Technology

3D printing technology has revolutionized the way we create objects. It allows you to make things layer by layer. Understanding its basics is crucial for beginners and pros. You need to grasp how 3D printers work. They use materials like plastic filament to build models. This technology can seem overwhelming at first. It's okay to feel lost. You will learn as you go.

Here are a few tips to get started. Always calibrate your printer before use. This ensures accurate prints. Take your time with designs. Rushing can lead to mistakes. Use clear, simple shapes to practice. They are easier to print and modify. Don’t hesitate to check community forums for advice. Many have faced the same challenges you will.

Mistakes happen. Failure is part of the journey. A print may collapse or warp. Reflect on what went wrong. Maybe the temperature was off. Perhaps the bed was not level. Use these moments to improve. Learning to troubleshoot will enhance your skills. Embrace the process. Each failure is a step towards mastery.

Choosing the Right 3D Printer for Your Needs

Choosing the right 3D printer is crucial for both beginners and experienced users. It's not just about the cost, but also about understanding your specific needs. According to industry reports, around 40% of users report dissatisfaction with their printer choice. This often stems from selecting a model that doesn't align with their goals.

For beginners, it's essential to evaluate the type of prints you want to create. Do you need high precision or speed? The layer resolution can vary significantly. For example, some entry-level printers offer 200 microns, while more advanced options can go as low as 50 microns. In a survey, 60% of professional users prioritize resolution in their purchasing decisions, highlighting its importance in achieving fine detail.

Material compatibility plays a role as well. Not all printers handle every filament type effectively. Common materials like PLA or ABS are user-friendly, but advanced users might require printers that support Nylon or carbon fiber. A poorly matched printer can lead to failed prints or extruder jams, leading to frustration. Thus, understanding the limitations and potential of your chosen 3D printer can make or break your printing experience.

Essential Materials for 3D Printing: Types and Uses

When you start 3D printing, the choice of materials plays a crucial role. Different types of filament can yield various results. For beginners, PLA is often the best choice. It’s easy to use and works well with most printers. It comes in many colors, making it visually appealing. However, PLA can be brittle. For those crafting durable items, exploring ABS might be worthwhile. ABS is stronger and withstands higher temperatures. Yet, it can release fumes during printing. Ventilation is vital when using it.

For more advanced users, PETG offers a unique balance. It's stronger than both PLA and ABS, and it's less prone to warping. This material is a solid option for functional parts. However, it can be tricky to print with due to its tendency to string. Support structures may be needed, and they can be challenging to remove. Balancing the right settings can be a nuanced art. Many users find themselves repeatedly adjusting to achieve quality prints. Consider experimenting with various materials to understand their properties better. Learning takes time, and mistakes are part of the journey.

Common Printing Issues and How to Troubleshoot Them

3D printing can be a rewarding hobby, but common issues can arise. One frequent problem is warping. This happens when the first layer doesn’t stick properly. Ensure your print bed is leveled and clean before starting. Using a heated bed can help keep the model flat during printing.

Another challenge is stringing. This occurs when the nozzle leaks filament while moving between parts. To minimize it, adjust the retraction settings. Increase the retraction distance or speed. You might also lower the temperature slightly to reduce flow during non-printing movements.

Over-extrusion can also cause issues. It leads to blobs and uneven surfaces. Check your filament diameter and adjust flow settings in your slicer. Taking the time to calibrate your printer significantly improves print quality. Don't skip this step, even if it’s tedious. Reflections on these issues can lead to better results in future prints.

Advanced Techniques for Optimizing Your 3D Prints

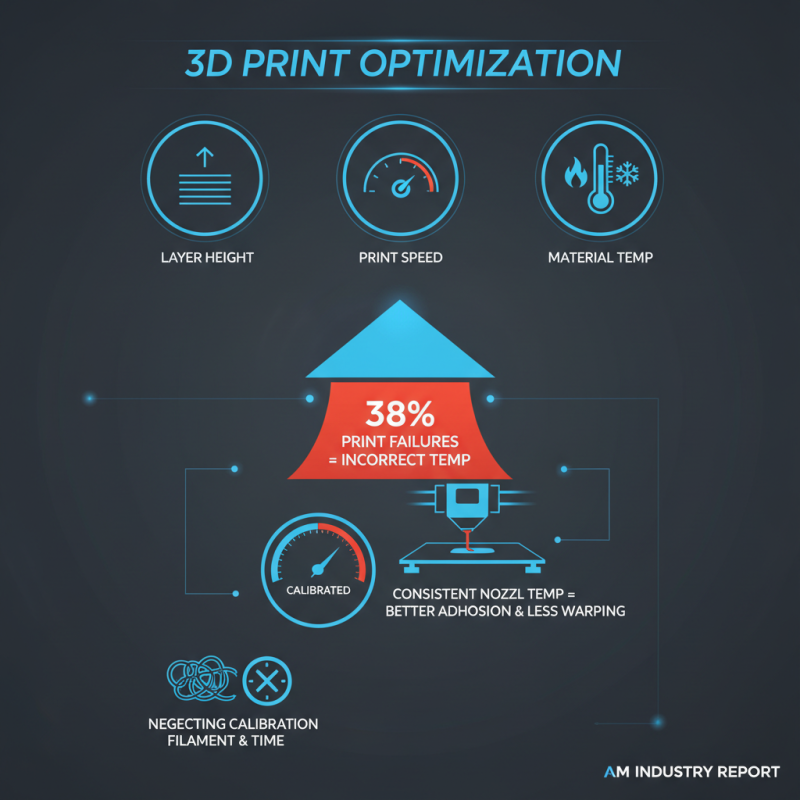

When optimizing 3D prints, attention to detail matters significantly. Layer height, print speed, and material temperature are crucial elements. According to a report from the Additive Manufacturing Industry, 38% of print failures stem from incorrect temperature settings. This highlights the importance of calibrating your printer appropriately. A consistent nozzle temperature ensures adhesion and reduces warping. Yet, many beginners neglect this step, leading to wasted filament and time.

Advanced techniques can elevate your prints. Using a heated bed can improve adhesion and reduce warping risks, especially with certain plastics. Reports indicate that 25% of users overlook this feature, resulting in subpar outcomes. Additionally, experimenting with infill patterns can enhance structural integrity. Varying the infill density affects both strength and weight. Many new users stick to default settings, missing out on improved performance through experimentation.

Monitoring your environment is vital too. Ambient temperature plays a significant role in print quality. A stable environment minimizes unexpected fluctuations, which can compromise adhesion. A surprising 30% of failures are attributed to environmental factors. Reflecting on these aspects can lead to better results in your 3D printing endeavors.

Related Posts

-

Unlocking the Future of Creativity with 3D Printers for Every Home

-

The Future of Creative Production with 3D Plastic Printers

-

Challenges Faced by Businesses in Adopting Commercial 3D Printers

-

Why Laser Sintering 3D Printers Are Revolutionizing Manufacturing Efficiency by 30%?

-

Exploring the Future of 3D Metal Printing Technology and Its Impact on Manufacturing Efficiency

-

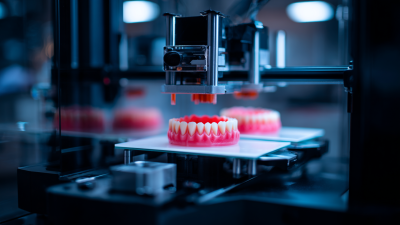

Revolutionizing Oral Care: The Impact of Dental 3D Printers on Modern Dentistry