Top 10 Benefits of Using a Ceramic 3D Printer for Your Projects

In recent years, the adoption of 3D printing technology has revolutionized various industries, with ceramic 3D printers at the forefront of this transformation. According to a report from SmarTech Analysis, the global market for 3D printed ceramics is projected to reach $4.8 billion by 2025, reflecting the growing interest and investment in this innovative technology. The unique properties of ceramics, such as their high-temperature resistance, durability, and aesthetic appeal, make ceramic 3D printers an attractive option for a myriad of applications ranging from industrial parts manufacturing to bespoke art pieces.

With advancements in print resolution and material versatility, ceramic 3D printers are enabling designers and engineers to push the boundaries of traditional manufacturing. A study by Wohlers Associates indicates that the additive manufacturing sector, which includes ceramic printing, has witnessed a cumulative annual growth rate of 25%, demonstrating the increasing reliance on this technology for complex geometries that were once deemed impossible or prohibitively expensive. As the capabilities of ceramic 3D printers continue to improve, the potential benefits of integrating this cutting-edge technology into projects cannot be underestimated, making it essential for professionals across various sectors to explore its advantages in detail.

Table of Contents

[Hide]

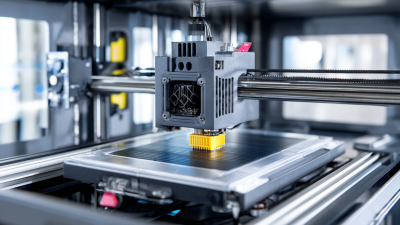

Understanding Ceramic 3D Printing Technology

Ceramic 3D printing technology has emerged as a revolutionary approach in various industries, providing the ability to create intricate designs with enhanced material properties. Combining traditional ceramics' benefits with cutting-edge additive manufacturing processes, it allows for greater design flexibility and improved efficiency. According to a report by the 3D Printing Industry, the ceramic market is projected to grow by over 15% annually, indicating a rising interest in advanced techniques that ceramic 3D printers offer. These printers enable the manufacturing of not only functional components but also artistic pieces that require high precision and aesthetic value.

Tips for successful ceramic 3D printing include ensuring proper material preparation and monitoring environmental conditions. For instance, maintaining optimal humidity levels can significantly reduce the risk of cracking during the drying process. Additionally, it's crucial to select the right printing parameters, such as temperature and speed, which can influence the final product's strength and surface finish. According to a study published by the Journal of Industrial Technology, adjusting these variables can lead to an increase in mechanical properties by up to 20%, demonstrating the importance of meticulous optimization in achieving desired outcomes.

The benefits of ceramic 3D printing extend to rapid prototyping and reduced material waste, making it an environmentally friendly option. With an increasing emphasis on sustainability in manufacturing, this technology allows for innovative solutions that minimize excess material usage while enabling faster iteration cycles during the design phase. The ability to create complex geometries that traditional methods may struggle to achieve opens up new avenues in various applications, from aerospace to medical devices, showcasing the transformative potential of ceramic 3D printing.

Enhanced Design Flexibility with Ceramic 3D Printers

Ceramic 3D printers offer unparalleled design flexibility, enabling creators to push the boundaries of what is possible in fabrication. With the ability to print complex geometries and intricate details, designers can produce unique components that would be challenging or even impossible to achieve through traditional manufacturing methods. This enhanced design capability allows for more innovative product development that meets specific aesthetic and functional requirements.

Moreover, the adaptability of ceramic materials opens the door to a wide range of applications, from intricate art pieces to high-performance industrial components. The precision and versatility of 3D printing technology empower designers to iterate quickly, making modifications on-the-fly without incurring significant costs or delays. This dynamic process not only fosters creativity but also accelerates the prototyping phase, giving designers a competitive edge in their respective fields. As a result, the integration of ceramic 3D printing into projects is transforming how ideas materialize and inspiring a new wave of imaginative solutions.

Improved Material Properties of Ceramic Parts

The use of ceramic materials in 3D printing has gained significant traction due to their enhanced material properties, making them ideal for various industrial applications. Ceramic parts produced through additive manufacturing showcase improved mechanical strength, thermal stability, and chemical resistance compared to traditional manufacturing methods. For instance, a report from the International Journal of Applied Ceramic Technology highlights that 3D-printed ceramics can exhibit flexural strengths exceeding 300 MPa, which is a notable improvement over conventional ceramics. This advancement opens new avenues for industries such as aerospace, automotive, and medical applications.

One of the key advantages of using ceramic 3D printers is the precision with which intricate geometries can be achieved. This level of detail allows for the production of complex components that would be otherwise difficult or impossible to create using traditional methods. Additionally, ceramic parts can be customized to meet specific functional requirements, reducing the need for additional machining processes, which can be cost-effective and time-saving.

Tips: When considering ceramic 3D printing, it's crucial to use the right slicing software and ensure optimal support structures to prevent warping during the printing process. Additionally, conducting preliminary tests on small-scale projects can help identify the most suitable ceramic materials for your final applications. Always stay informed about the latest advancements in ceramic materials to leverage their full potential in your projects.

Cost-Effectiveness in Prototyping with Ceramic Materials

When it comes to prototyping, the cost-effectiveness of using a ceramic 3D printer cannot be overstated. A report from the Wohlers Associates indicates that companies utilizing additive manufacturing for prototyping can reduce material costs by up to 70% compared to traditional subtractive methods. This significant savings is primarily due to the ability of 3D printers to create complex geometries with minimal waste, which is especially beneficial when working with ceramic materials that typically have higher material costs.

Furthermore, ceramic 3D printing allows for rapid prototyping cycles, reducing the time from concept to production. According to a study by Research and Markets, the additive manufacturing market for ceramics is expected to grow at a CAGR of over 20% in the next five years. This acceleration means businesses can iterate and refine their designs without incurring prohibitive expenses, enhancing innovation while remaining budget-conscious.

Tip: When prototyping with ceramic 3D printers, consider optimizing your design for efficiency. Simplifying part geometries can reduce both print time and material usage. Additionally, keep an eye on the evolving technologies in this space, as advancements continue to lower operational costs and expand design possibilities.

Tip: Collaborate with engineers and designers early in the prototyping phase. Early involvement can help identify potential design flaws that could lead to higher costs if discovered later in the production process. This proactive approach can help maintain the cost-effectiveness of your ceramic prototyping projects.

Environmental Benefits of Using Ceramic in 3D Printing

The environmental benefits of using ceramic in 3D printing are significant and multifaceted. Ceramic materials, derived from natural resources, are not only abundant but also generate less waste during the manufacturing process compared to traditional methods. By utilizing additive manufacturing techniques, ceramic 3D printing minimizes material use, reducing the overall carbon footprint. This allows for precise fabrication, which means that less raw material is wasted, contributing to more sustainable production practices.

Moreover, ceramic 3D printing supports the creation of biodegradable and environmentally friendly products. Unlike some plastics, ceramics do not release harmful chemicals into the environment when disposed of, making them a safer choice for both consumers and the planet. Additionally, ceramics are often more energy-efficient in terms of production and can withstand higher temperatures, which makes them suitable for a variety of applications, from construction to art. As industries increasingly prioritize sustainability, the integration of ceramic materials into 3D printing ushers in a new era of eco-friendly manufacturing that aligns with global efforts to reduce environmental impact.

Related Posts

-

Exploring the Future of 3D Metal Printing Technology and Its Impact on Manufacturing Efficiency

-

How to Choose the Right SLS Printer for Your Business: A Data-Driven Guide

-

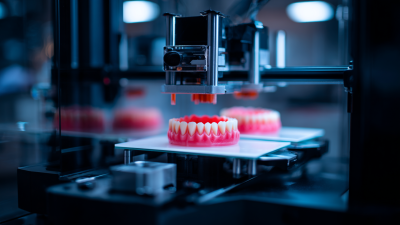

Revolutionizing Oral Care: The Impact of Dental 3D Printers on Modern Dentistry

-

The Future of Creative Production with 3D Plastic Printers

-

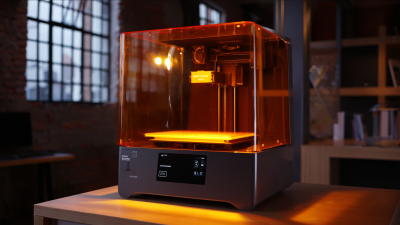

Exploring the Future of 3D Printing with DLP Resin Technology

-

How to Optimize Your Workflow with a Professional 3D Printer: Insights from Industry Experts