Top Benefits of Using a Powder 3D Printer for Your Projects

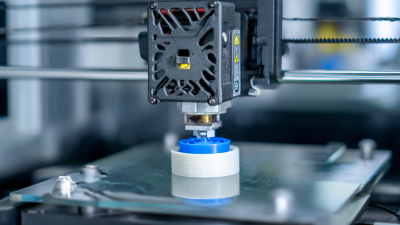

The advent of the powder 3D printer has revolutionized the landscape of additive manufacturing, providing a range of benefits that are making significant waves across various industries. According to Dr. Emily Chen, a renowned expert in 3D printing technologies, "The powder 3D printer not only enhances design flexibility but also allows for the production of complex geometries that were previously unattainable." This assertion underscores the key advantages that this technology brings to the table, particularly in fields such as aerospace, automotive, and healthcare.

One of the standout features of a powder 3D printer is its ability to create lightweight yet durable components, a benefit that enables engineers and designers to push the boundaries of innovation. By utilizing powdered materials, these printers can produce intricate designs while minimizing waste, ultimately resulting in more sustainable manufacturing practices. In a world where efficiency and environmental impact are paramount, the powder 3D printer emerges as a critical tool that meets the demands of modern project requirements.

As we delve deeper into the top benefits of using a powder 3D printer for your projects, it becomes clear that embracing this technology is not just a trend; it's a strategic decision that can lead to enhanced productivity, reduced costs, and unparalleled creative potential.

Table of Contents

[Hide]

Advantages of Powder 3D Printing Over Traditional Methods

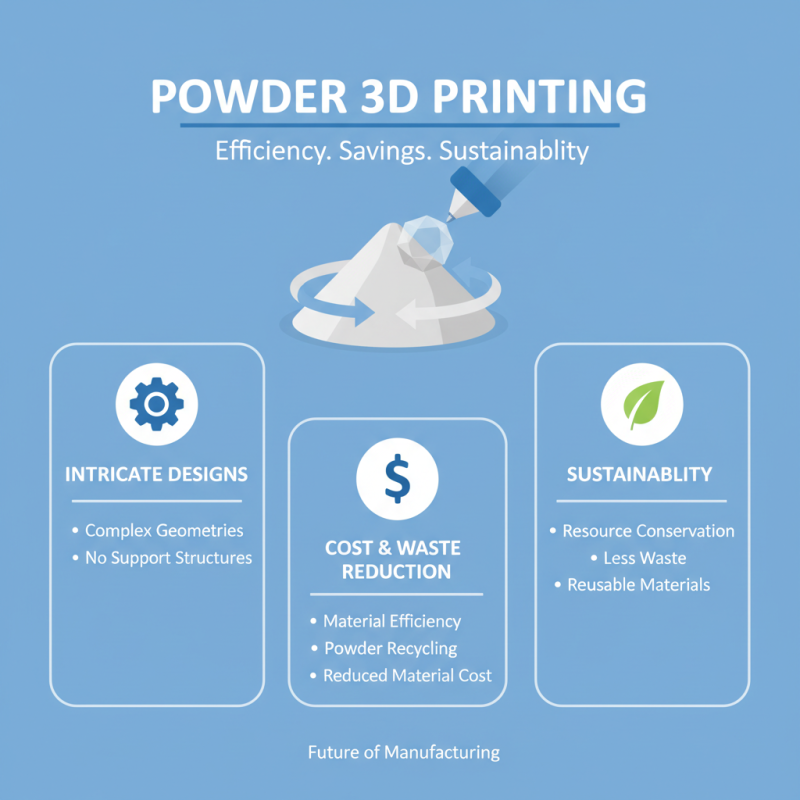

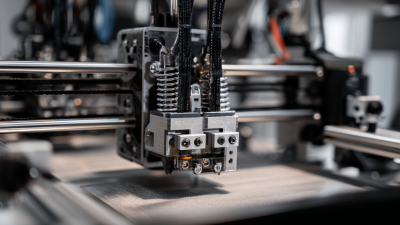

Powder 3D printing is rapidly gaining attention as a superior alternative to traditional manufacturing methods. One of the most significant advantages is its ability to create highly complex geometries with ease, which often proves difficult or impossible with conventional techniques. Unlike subtractive manufacturing, where material is carved away to achieve the desired shape, powder 3D printing builds objects layer by layer from a digital model. This process minimizes waste, making it an environmentally friendly option while also reducing production costs.

Additionally, powder 3D printing offers unparalleled design flexibility. Designers can produce intricate details and customized parts that are tailored for specific applications. This level of personalization goes beyond what is typically achievable with traditional methods, allowing for innovative solutions in various industries, including aerospace, automotive, and healthcare. By using powdered materials, manufacturers can also create lighter structures without compromising strength, which is crucial in applications where weight reduction is vital.

**Tip:** When starting a powder 3D printing project, always optimize your design for the specific material you plan to use. Experimenting with different powder compositions can yield better mechanical properties and surface finishes, enhancing the overall quality of the final product.

**Tip:** Ensure proper settings and calibrations on your printer for the best results. Variations in temperature and powder layer thickness can lead to different outcomes, so fine-tuning these parameters is essential to achieving consistent quality throughout your production runs.

Top Benefits of Using a Powder 3D Printer for Your Projects

Enhanced Material Versatility in Powder 3D Printing

One of the standout advantages of powder 3D printing is its enhanced material versatility. Unlike traditional methods, which often rely on a limited number of materials, powder 3D printing allows for a wide range of materials to be used, including metals, polymers, ceramics, and composite materials. This flexibility enables designers and engineers to select the most suitable material for their specific application, enhancing the functionality and performance of the final product. For instance, industries such as aerospace and automotive benefit significantly from the ability to work with lightweight yet strong materials that can withstand extreme conditions.

Moreover, the powder bed fusion process opens the door to innovative material combinations that can be tailored for unique applications. By blending different powders, manufacturers can achieve customized properties, such as improved thermal resistance or enhanced mechanical strength. This capability not only fosters creativity in product design but also allows for the production of parts with specific attributes that are difficult to achieve with conventional manufacturing techniques. As a result, projects across various sectors, including medical, industrial, and consumer goods, can leverage this versatility to push the boundaries of what is possible in 3D printing.

Top Benefits of Using a Powder 3D Printer for Your Projects - Enhanced Material Versatility in Powder 3D Printing

| Benefit | Description | Material Types Supported |

|---|---|---|

| Complex Geometries | Ability to create intricate designs that traditional methods cannot achieve. | Metals, Ceramics, Plastics |

| Material Efficiency | Minimizes waste by using only what is necessary for the print. | Plastics, Composites |

| Customization | Easy to tailor designs to specific needs or preferences. | Metals, Polymers |

| Rapid Prototyping | Quickly create prototypes for testing and validation. | Plastics, Metals |

| Durability | Produces strong and long-lasting parts suitable for functional use. | Metals, Advanced Plastics |

| Reduced Lead Times | Shortens production time compared to traditional methods. | Various Types |

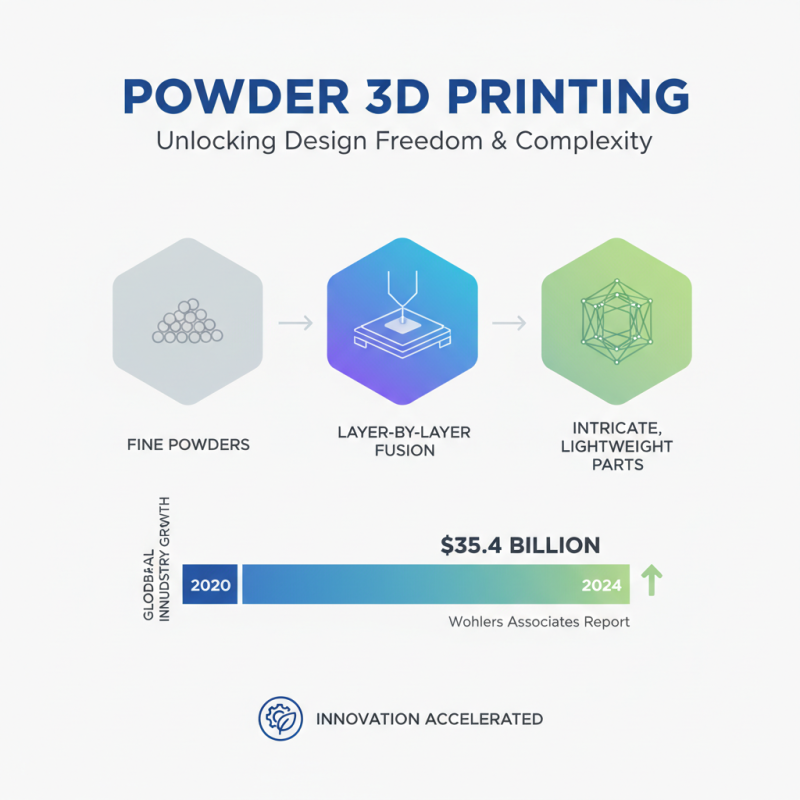

Improved Design Freedom and Complexity with Powder Technology

The integration of powder technology in 3D printing introduces a transformative approach to design freedom and complexity. Unlike traditional manufacturing methods, powder 3D printing allows for intricate geometries and complex structures that were once deemed impractical or impossible. According to a report by Wohlers Associates, the additive manufacturing industry is projected to reach $35.4 billion by 2024, with significant contributions from powder-based technologies. This growth is largely driven by the capability of powder printers to produce lightweight yet robust components, enabling designers to push the boundaries of innovation.

One of the key advantages of powder 3D printing is its ability to create optimized designs that maximize material usage while minimizing weight. This is particularly beneficial in industries such as aerospace and automotive, where reducing weight can have a profound impact on fuel efficiency and performance. A study published in the Journal of Manufacturing Processes revealed that components produced using powder technology can achieve a reduction in weight by up to 50% compared to traditionally manufactured parts, without sacrificing structural integrity. This capability not only enhances the performance of products but also encourages sustainable practices by reducing material waste and energy consumption in production.

Moreover, the versatility of powder materials, including metals and polymers, opens up new avenues for creativity and experimentation. Designers can iterate quickly, test various configurations, and refine their ideas without the limitations set by conventional manufacturing processes. This flexibility fosters innovation and allows for custom solutions tailored to specific project needs, showcasing the paramount role of powder technology in modern design and manufacturing landscapes.

Cost Efficiency and Reduced Waste in Powder 3D Printing Processes

Powder 3D printing has emerged as a highly efficient method for producing intricate designs while minimizing costs and waste. One of the most significant advantages of this technology is its ability to utilize materials more effectively compared to traditional manufacturing techniques. In powder-based processes, unused powder can often be recycled and reused in future prints, significantly reducing the overall material expenditure. This recycling capability not only conserves resources but also translates into cost savings for businesses and individual makers, making it a more sustainable option in the long run.

Furthermore, the layer-by-layer approach of powder 3D printing allows for the fabrication of complex geometries that are lightweight yet durable. Traditional methods often require additional material to ensure structural integrity, leading to more waste during production. In contrast, powder 3D printing can produce intricate parts with less material without compromising strength. This efficiency in material use contributes to lower overhead costs, as manufacturers spend less on raw materials while also addressing the growing demand for environmentally friendly production methods. By prioritizing cost efficiency and waste reduction, powder 3D printing not only benefits project budgets but also aligns with contemporary sustainability goals.

Applications and Industries Benefiting from Powder 3D Printing

Powder 3D printing is rapidly advancing across various industries, proving to be a game-changer for sectors like aerospace, automotive, and healthcare. According to a report by Research and Markets, the global metal 3D printing market is expected to reach $1.07 billion by 2025, driven significantly by the efficiency and customization capabilities offered by powder-based technologies. This method allows for the creation of lightweight, intricate components that traditional manufacturing processes struggle to achieve, thereby reducing material waste and production times.

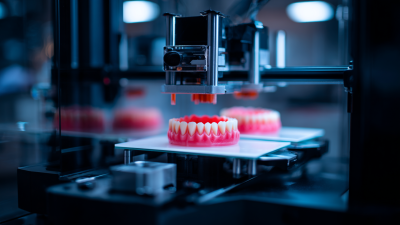

In the aerospace industry, for instance, companies are utilizing powder 3D printing to produce complex turbine blades that optimize engine performance and reduce emissions. The ability to print geometrically complex shapes not only enhances performance but also contributes to substantial weight savings. Similarly, the healthcare sector is taking advantage of powder 3D printing to produce bespoke implants and prosthetics tailored to individual patients, improving surgical outcomes and recovery times.

Tip: When considering powder 3D printing for your projects, it's essential to thoroughly assess the specific requirements of your application. Ensuring the right material compatibility can significantly impact the durability and performance of the final product.

Moreover, industries such as tooling and electronics are also recognizing the advantages of powder-based 3D printing. The ability to create custom molds and durable parts on-demand has revolutionized production processes, leading to decreased lead times and increased design flexibility.

Tip: Collaborating with industry experts can provide valuable insights into optimizing the design for powder 3D printing, ensuring that you leverage the full potential of this innovative technology.

Related Posts

-

How to Choose the Right Dental 3D Printer for Your Practice Needs

-

Revolutionizing Oral Care: The Impact of Dental 3D Printers on Modern Dentistry

-

Exploring the Impact of Polymer 3D Printers at the 138th China Import and Export Fair 2025

-

Exploring the Future of 3D Metal Printing Technology and Its Impact on Manufacturing Efficiency

-

Innovative Solutions for Enhancing Production with Powder 3D Printers

-

Digital Revolution Best 3D Printers That Print Metal Transforming Manufacturing Efficiency