Best Ball Screws for Sale What to Look For?

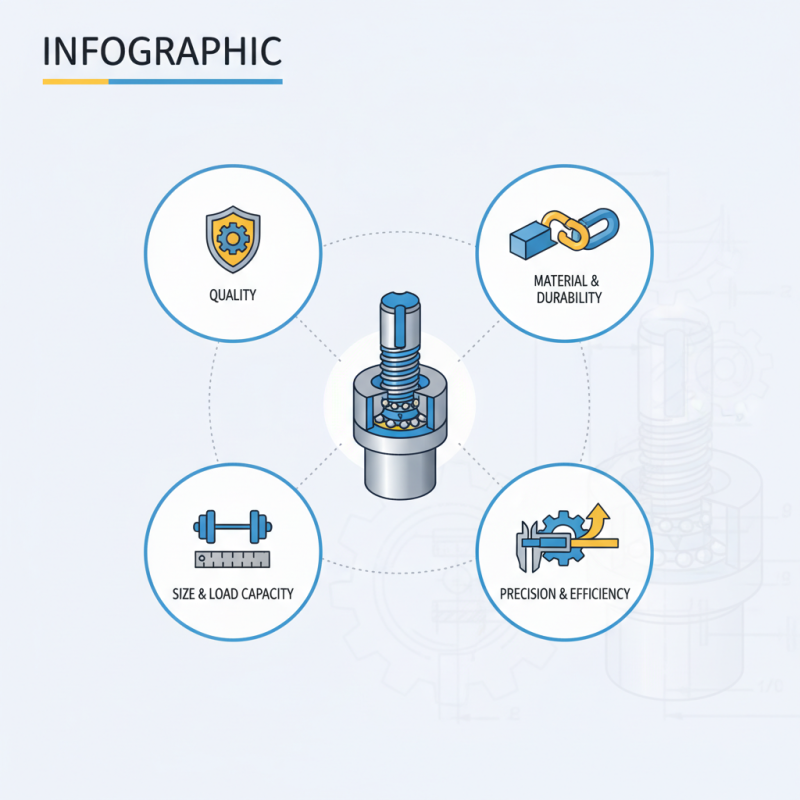

When searching for a "ball screw for sale," it's essential to understand what factors matter most. This guide will explore the key features to consider. Ball screws are critical components in many machinery applications. They enhance precision and improve efficiency. Choosing the right one can be overwhelming.

Quality is vital. Look for durability and reliability. The material used can greatly affect performance. You might find various sizes and load capacities. Each has its applications. Don't rush this process. An impulsive choice might lead to poor performance.

Manufacturers often provide specifications online. Take your time to compare options. It's okay to feel unsure or confused. Seek advice if necessary. Remember, an informed decision can save time and money in the long run. Prioritize your needs, and you'll find the best ball screw for your project.

Table of Contents [Hide]

Understanding Ball Screws: Definition and Functionality

Ball screws are critical components in various machinery. Their primary role is to convert rotational motion into linear motion with high efficiency. Engineered with a ball recirculation system, they reduce friction and wear. This enhances the lifespan of equipment and boosts overall performance. According to industry reports, ball screws can achieve up to 90% efficiency. This is significantly higher than traditional lead screws.

Understanding the construction of ball screws is essential. They typically comprise a screw shaft, nut, and a series of balls. The balls roll between the nut and the screw, allowing smooth movement. Researchers indicate that precision in manufacturing can notably influence the performance of ball screws. A slight deviation in diameter can cause misalignment, leading to reduced efficiency. In fact, studies show that even a 0.01 mm error can impact operational accuracy.

Choosing the right ball screw requires careful consideration. Factors like load capacity, speed, and material choice matter. Not all applications need the same specifications. A mismatch can lead to failure or inefficiency. Recent surveys indicate that many engineers often overlook these details, leading to costly mistakes. Proper evaluation can prevent these issues and ensure optimal operation.

Key Factors to Consider When Purchasing Ball Screws

When purchasing ball screws, it's essential to consider several key factors. First, accuracy is critical. A 2019 industry report indicated that high-precision ball screws can improve machine accuracy by up to 80%. This can significantly enhance the performance of CNC machines and other precision tools. Look for screws that specify their accuracy grade. There are different grades of precision, which offer various tolerances.

Another factor to consider is load capacity. Ball screws must handle the expected load without deformation over time. According to the latest market research, many manufacturers test their load capacities rigorously. Choosing the right size ensures longevity. Materials used in manufacturing ball screws are equally important. High-grade steel or treated materials enhance durability. It's worth noting that lower-quality screws may save money upfront but could lead to increased maintenance costs later.

Finally, you should consider the lead time for delivery. A report from 2022 highlighted that lead time can vary significantly among suppliers. Delays can hinder production schedules. Assess whether the supplier can provide timely delivery without compromising quality. Paying attention to these factors can prevent costly mistakes in the future. Investing in the right ball screws is crucial for operational efficiency.

Comparison of Key Factors to Consider When Purchasing Ball Screws

Types of Ball Screws and Their Applications

When considering ball screws, it's crucial to understand the different types available. Each type has unique characteristics and applications. For instance, there are standard ball screws, which are commonly used in CNC machines. They provide excellent precision and efficiency. Another type is the flange type, which simplifies mounting. This design often benefits automated systems, where space efficiency is key.

Then we have the miniature ball screws. These are perfect for compact applications, such as medical devices or robotics. They allow for precise movement in tight spaces. However, they may not handle heavy loads as well as larger screws do. Choosing the right type depends on specific needs and load capacities.

It’s essential to reflect on your application requirements. Not every ball screw will fit every situation. Sometimes, buyers focus too much on specifications and overlook installation factors. For any mechanical setup, dimensions, and mounting are equally important. Skipping this can lead to performance issues later. Each choice requires careful consideration to ensure optimal functionality.

Quality Indicators and Standards for Ball Screws

When searching for high-quality ball screws, attention to quality indicators is crucial. Look for components made from premium materials like stainless steel or hardened alloys. These materials provide strength and durability, reducing the risk of failure. A report from the Precision Engineering Society notes that properly selected materials can enhance lifespan by up to 30%.

Tip: Always check the material specifications before purchasing. Specifications often provide insight into the performance capabilities of the ball screws.

Accuracy and precision are vital in ball screws. Pay attention to the lead accuracy, which typically ranges from ±0.02 mm to ±0.1 mm. Poor lead accuracy can result in machinery malfunction or increased wear. A well-rated ball screw should meet industry standards like ISO 3408.

Tip: Consider asking for test reports. These documents can prove compliance with quality standards.

Lastly, don't overlook the importance of lubrication systems. A good lubrication system ensures smooth operation. Neglecting this aspect can lead to wear and reduce performance.

Tip: If unsure, consult a professional for recommendations based on your specific application.

Where to Source Reliable Ball Screws for Sale

When looking for reliable ball screws, quality is key. These components are crucial for precision machinery. They are used in automation, robotics, and CNC machines. Finding a trustworthy supplier can seem overwhelming. Many options are available, but not all offer the same standards.

Start by checking online marketplaces. Look for suppliers with high ratings and positive reviews. Pay attention to customer feedback. It can reveal a lot about their reliability. Also, consider specialized industrial suppliers. They often have a wider selection. Their products are typically of higher quality.

Visiting trade shows can be beneficial too. You can see the products firsthand and talk to representatives. It helps to discuss specifications directly. However, don’t forget to compare prices. Some suppliers may charge more without adding extra value. Evaluate warranty and return policies as well. It’s essential to ensure you’re making a wise investment in your machinery.

Best Ball Screws for Sale - What to Look For?

| Ball Screw Type | Diameter (mm) | Lead (mm) | Material | Load Capacity (N) | Price (USD) |

|---|---|---|---|---|---|

| Standard Ball Screw | 20 | 5 | Steel | 5000 | 120 |

| Miniature Ball Screw | 12 | 2 | Aluminum | 1200 | 75 |

| Precision Ball Screw | 25 | 10 | Carbon Steel | 8000 | 150 |

| High Load Ball Screw | 30 | 12 | Alloy Steel | 10000 | 200 |

| Ground Ball Screw | 20 | 5 | Stainless Steel | 6000 | 130 |