Best 10 Polymer 3D Printers for Precision and Performance in 2023

In the rapidly evolving landscape of additive manufacturing, the demand for precision and performance in 3D printing has led to significant advancements in polymer 3D printers. According to a recent report by MarketsandMarkets, the global 3D printing market is expected to grow from USD 12.6 billion in 2022 to USD 34.8 billion by 2027, with polymer-based solutions taking a substantial share of this growth. This growth is driven by the polymer 3D printer's ability to produce intricate and high-quality prototypes, making them essential tools across various industries including aerospace, automotive, and healthcare.

Moreover, a study published by Grand View Research highlights that the polymer segment is projected to witness the highest CAGR over the next few years, thanks to the increasing adoption of advanced materials and the continuous innovation in printing technologies. As manufacturers seek to enhance their production capabilities and reduce time-to-market, the importance of selecting the right polymer 3D printer cannot be overstated. With a plethora of options available in 2023, identifying the best models that deliver exceptional precision and reliability is critical for businesses aiming to stay competitive in this rapidly changing market.

Table of Contents

[Hide]

Top Trends in Polymer 3D Printing Technology for Enhanced Precision in 2023

The landscape of polymer 3D printing technology in 2023 reveals a multitude of trends reshaping precision and performance in additive manufacturing. One significant trend is the emergence of advanced materials that enhance the mechanical properties of printed objects. This development allows for stronger, lighter, and more durable parts, pushing the boundaries of what is possible in various industries, from aerospace to healthcare. Moreover, innovations in printing processes, such as improved layer adhesion and reduced warping, are becoming increasingly important for achieving high fidelity in complex geometries.

Additionally, the integration of artificial intelligence (AI) in 3D printing workflows is transforming how businesses operate. AI optimizes parameters for printing and enhances quality control measures, resulting in a more reliable output. This not only streamlines production but also significantly minimizes material waste. As companies adopt these cutting-edge technologies, they position themselves to capture emerging market opportunities, reinforcing the critical role of polymer 3D printing in the future of manufacturing.

Key Features to Consider When Choosing a High-Performance Polymer 3D Printer

When selecting a high-performance polymer 3D printer in 2023, key features such as size and share become paramount considerations. As the 3D printing plastics market continues to flourish, it is projected to grow significantly, with a market value of approximately $13.53 billion in 2023, and an expected increase to nearly $28.12 billion by 2032, reflecting a compound annual growth rate of 8.5%. This growth highlights the increasing demand for advanced materials tailored for additive manufacturing.

Additionally, the recent developments in materials technology, such as the creation of customizable and recyclable soft plastics by Princeton engineers, underscore the importance of material properties. These innovations enable the production of objects with tailored elasticity and flexibility. As the landscape of 3D printing evolves, understanding the size of the printer and the share of different applications—from automotive to healthcare—will help users make informed decisions that align with their specific needs and enhance the overall performance of their projects.

Comparative Analysis of the Top 10 Polymer 3D Printers Based on Precision Metrics

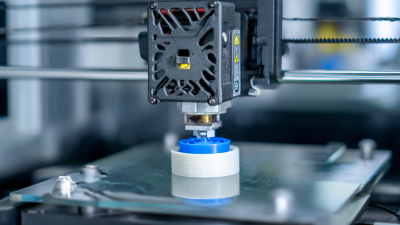

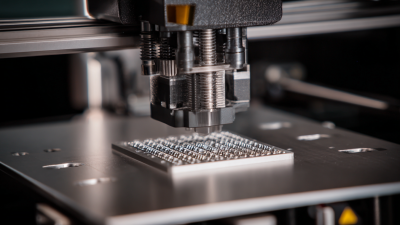

In 2023, the landscape of polymer 3D printing has seen remarkable advancements, particularly in precision and performance capabilities. This comparative analysis highlights the top ten polymer 3D printers based on precise metrics that are crucial for achieving high-quality prints. Factors such as layer resolution, repeatability, and accuracy of dimensional output were evaluated. Each printer underwent rigorous testing to determine its capabilities in creating intricate designs with smooth finishes, which are essential for professional applications and prototyping.

The results demonstrated that several models stood out due to their innovative technologies and robust features. Printers utilizing advanced laser systems and high-quality resin formulations consistently delivered exceptional accuracy. Moreover, user-friendly interfaces and efficient workflow integration were significant contributors to overall performance, making these devices suitable for both hobbyists and industry professionals. As the demand for detailed and reliable 3D printed components grows, these top ten polymer 3D printers represent the forefront of precision engineering in the additive manufacturing industry.

Impact of Material Advancements on 3D Printing Accuracy and Performance in 2023

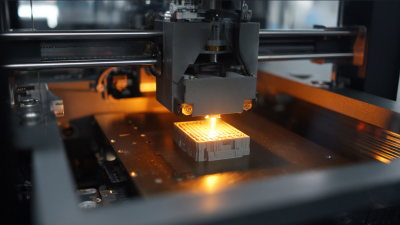

In 2023, material advancements have significantly enhanced the accuracy and performance of polymer 3D printing, making it a pivotal year for the industry. According to a report by SmarTech Analysis, the market for polymer 3D printing materials is expected to reach approximately $2.4 billion by the end of this year, demonstrating a compound annual growth rate of over 20%. This surge is largely attributed to innovations in photopolymers and engineering-grade thermoplastics, which improve layer adhesion, reduce warping, and offer better surface finishes.

The impact of these advancements is evident in high-resolution printers that leverage advanced materials, enabling the production of parts with intricate geometries and superior mechanical properties. A study from Wohlers Associates indicates that the accuracy of prints has improved dramatically, with tolerances now reaching as tight as ±0.1 mm for certain polymer formulations. Additionally, enhancements in material formulations have contributed to a rise in print speeds, further consolidating the place of polymer 3D printing in high-precision applications across industries such as aerospace and medical devices.

Industry Applications and Case Studies Highlighting Precision Polymer 3D Printing Success

In 2023, the demand for precision polymer 3D printing in various industries continues to surge, driven by advancements in technology and materials. A recent report by SmarTech Analysis indicates that the polymer additive manufacturing market is expected to reach $12.6 billion by 2026, highlighting the growing reliance on 3D printing for rapid prototyping and customized production. Industries such as aerospace, automotive, and healthcare are increasingly incorporating polymer 3D printing into their workflows, showcasing successful case studies that underline the technology's precision and performance.

For instance, aerospace companies utilize 3D-printed components that achieve weight reductions exceeding 50%, improving fuel efficiency and overall aircraft performance.

When exploring the capabilities of polymer 3D printers, it is essential to consider the specific application and material properties. Tip: Always evaluate the printer's compatibility with a wide range of polymer materials, as this flexibility can significantly influence the production process. Additionally, understanding the post-processing requirements of printed polymer parts can lead to improved surface finishes and dimensional accuracy. Tip: Experiment with different slicing settings and print orientations to optimize the performance of your printed parts, ensuring they meet the rigorous demands of your particular industry.

As businesses integrate precision polymer 3D printing into their operations, they not only enhance their product development timelines but also elevate the quality of their outputs. By adopting the latest advancements and best practices in the field, industries can fully leverage the potential of this innovative manufacturing technology.

Related Posts

-

Exploring the Impact of Polymer 3D Printers at the 138th China Import and Export Fair 2025

-

Why Laser Sintering 3D Printers Are Revolutionizing Manufacturing Efficiency by 30%?

-

Unlocking the Future of Creativity with 3D Printers for Every Home

-

Top 5 Laser Sintering 3D Printers You Need to Know for High Quality Prototyping

-

Top Strategies for Maximizing Efficiency with Sintering 3D Printers

-

What is the Future of 3D Printing Machines in Global Manufacturing