Challenges Faced by Businesses in Adopting Commercial 3D Printers

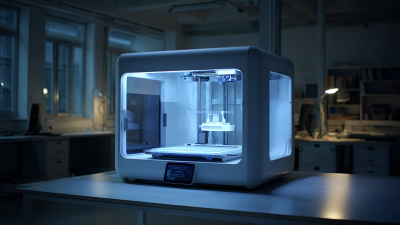

As the landscape of manufacturing continues to evolve, businesses are increasingly looking towards cutting-edge technologies to enhance their production processes. Among these, commercial 3D printers have emerged as a revolutionary tool, enabling companies to innovate and streamline operations. However, despite the numerous advantages that commercial 3D printers offer—such as cost-efficiency, customization, and reduced waste—there are significant challenges that organizations face when adopting this technology. This ultimate guide aims to explore these hurdles, ranging from the initial financial investment and the need for skilled personnel to concerns regarding technology integration and maintenance. By understanding these challenges, businesses can better prepare themselves to embrace commercial 3D printers and leverage their full potential in today’s competitive market.

Table of Contents

[Hide]

Challenges in Understanding the Technology Behind Commercial 3D Printers

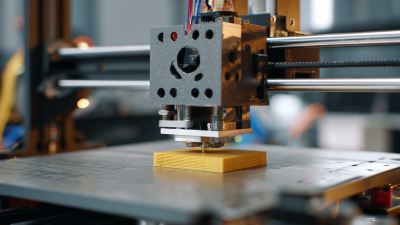

Understanding the technology behind commercial 3D printers can be a significant hurdle for businesses looking to integrate this innovative solution into their operations. Many companies find themselves overwhelmed by the vast array of printer types, material options, and the complexities of software used in the 3D printing process. This lack of understanding can lead to poor investment decisions and, ultimately, failed implementation.

To navigate this challenge, businesses should consider investing in training programs that provide in-depth knowledge about 3D printing technologies. Engaging with industry experts through workshops can help demystify the technology, ensuring teams are equipped to make informed decisions.

Additionally, collaborating with experienced vendors can offer tailored solutions that fit specific business needs, making the adoption process smoother and more efficient.

Another critical aspect is keeping up with rapid technological advancements. The 3D printing industry evolves quickly, which means that knowledge from even a few months ago can become outdated. Businesses should regularly participate in webinars and trade shows, staying informed about new materials and techniques. Embracing continuous learning can significantly enhance a company's ability to leverage 3D printing effectively.

Financial Implications: High Initial Costs vs. Long-Term Benefits

The financial implications of adopting commercial 3D printers present a significant dilemma for businesses. On one hand, the high initial costs of purchasing and maintaining advanced 3D printing technology can be daunting, especially for small and medium-sized enterprises. The investment in specialized equipment, materials, and training can quickly add up, creating a barrier to entry that many companies find challenging to overcome. This initial financial burden often leads businesses to hesitate, weighing whether the upfront expenses justify the potential returns.

On the other hand, the long-term benefits of integrating 3D printing into production processes can far outweigh these initial costs. Companies that embrace this technology often find they can significantly reduce material waste, streamline production times, and foster innovation in product design. Additionally, the ability to produce customized parts on demand can enhance customer satisfaction while lowering inventory costs. As businesses evaluate their financial strategies, understanding the balance between high initial investments and the substantial long-term advantages is crucial for making informed decisions about commercial 3D printing integration.

Material Limitations: Navigating the Complexities of 3D Printing Materials

The adoption of commercial 3D printers is becoming increasingly advantageous for businesses, yet one of the most significant hurdles they face is the complexity of 3D printing materials. According to a 2022 report from SmarTech Analysis, the 3D printing materials market is projected to reach $5 billion by 2027, highlighting the growing interest in this technology. However, varied material properties—such as strength, flexibility, and thermal resistance—add layers of difficulty in selecting the right material for specific applications.

Tip: When considering material options, businesses should conduct thorough research to understand the mechanical and thermal properties of each material, ensuring that they align with their project requirements. Utilizing material datasheets and reaching out to suppliers can provide insightful information.

Companies must also grapple with limited availability and high costs of certain premium materials. For instance, specialized thermoplastics like PEEK can cost up to $500 per kilogram, posing a significant barrier for frequent use. Therefore, businesses need to find a balance between performance and cost.

Tip: Experimenting with less expensive thermoplastics or resins in prototyping phases can help businesses mitigate costs while still achieving their product goals. Additionally, developing strong relationships with multiple suppliers could enhance material availability and lead to better pricing negotiations.

Workforce Skill Gaps: The Need for Training and Expertise in 3D Printing

The adoption of commercial 3D printers presents numerous challenges for businesses, one of the most significant being the workforce skill gap. According to a report by Wohlers Associates, the additive manufacturing industry is expected to grow to a $35.6 billion market by 2024, yet many companies struggle to find professionals with the requisite skills to harness this technology effectively. The complex nature of 3D printing requires not only technical expertise but also a deep understanding of design and materials science, making the need for specialized training critical.

Many organizations report that the lack of in-house expertise limits their ability to innovate and stay competitive. A survey by the Global Manufacturing and Supply Chain Practices revealed that 63% of manufacturers feel unprepared to integrate 3D printing into their operations due to insufficient training programs. To bridge this gap, businesses must invest in comprehensive training initiatives that provide hands-on experience with 3D printing technologies, covering everything from software use to material selection. Moreover, partnering with educational institutions can foster a new pipeline of talent skilled in additive manufacturing, ultimately enabling businesses to capitalize on the advantages that commercial 3D printers offer.

Challenges Faced by Businesses in Adopting Commercial 3D Printers - Workforce Skill Gaps: The Need for Training and Expertise in 3D Printing

| Challenge | Description | Impact on Business | Training Needs |

|---|---|---|---|

| Skill Gap | Lack of qualified personnel with 3D printing technology expertise. | Reduced efficiency and productivity in production processes. | Hands-on training in CAD software, additive manufacturing techniques. |

| Technological Adaptation | Difficulty in adapting existing processes to incorporate 3D printing technology. | Potential loss of competitive edge in product development. | Workshops on integrating 3D printing with current workflows. |

| Cost of Training | High costs associated with training programs and equipment. | Budget constraints may limit ability to implement 3D printing. | Investments in affordable online courses and software training. |

| Quality Control | Ensuring the quality of 3D printed products meets industry standards. | Risk of producing non-compliant products leading to recalls. | Certification courses in quality assurance and inspection methodologies. |

| Innovation | Limited creativity due to lack of knowledge about advanced materials and designs. | Stagnation in product innovations reducing marketability. | Training in new materials, design thinking and prototyping techniques. |

Integration Issues: Combining 3D Printing with Existing Manufacturing Processes

Integrating commercial 3D printers into existing manufacturing processes can present significant challenges for businesses. One of the most pressing issues is the compatibility of new technologies with established workflows. Companies often struggle with how to effectively merge additive manufacturing techniques with traditional subtractive methods. This can lead to inefficiencies and increased production times if not managed properly.

Tip: To ensure a smooth integration, businesses should invest time in training their workforce on 3D printing technologies. Understanding the capabilities and limitations of 3D printers can help teams better envision how these tools fit into their current processes.

Additionally, there can be difficulties related to material compatibility and equipment calibration. Many companies find that the materials used in 3D printing, such as thermoplastics and metal powders, may not seamlessly align with their existing systems. It’s crucial to evaluate and possibly revise material specifications and supplier relationships to fully leverage 3D printing's advantages.

Tip: Conducting thorough testing and pilot programs before a full-scale rollout can help identify potential integration issues early on. This allows businesses to make informed decisions and adjustments that enhance the efficiency of the manufacturing process with 3D printing technology.

Challenges Faced by Businesses in Adopting Commercial 3D Printers

This bar chart illustrates the various challenges faced by businesses when integrating commercial 3D printers into their existing manufacturing processes. The data shows the percentage impact of several key issues: Integration Issues (35%), High Initial Costs (25%), Skill Gap (20%), Material Limitations (10%), and Quality Control (10%).