How to Choose the Right SLS Printer for Your Business: A Data-Driven Guide

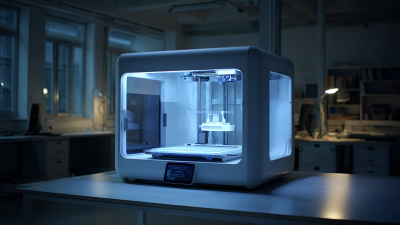

In today's rapidly evolving manufacturing landscape, the choice of the right SLS printer is crucial for businesses aiming to stay competitive and innovative. Selective Laser Sintering (SLS) technology offers unparalleled advantages, including the ability to produce complex geometries and robust prototypes. However, with a myriad of SLS printers available on the market, selecting the ideal model for your specific business needs can be a daunting task. This guide aims to simplify the decision-making process by providing a data-driven approach, focusing on key factors such as build volume, material compatibility, and cost-effectiveness.

In today's rapidly evolving manufacturing landscape, the choice of the right SLS printer is crucial for businesses aiming to stay competitive and innovative. Selective Laser Sintering (SLS) technology offers unparalleled advantages, including the ability to produce complex geometries and robust prototypes. However, with a myriad of SLS printers available on the market, selecting the ideal model for your specific business needs can be a daunting task. This guide aims to simplify the decision-making process by providing a data-driven approach, focusing on key factors such as build volume, material compatibility, and cost-effectiveness.

Whether you are a startup exploring 3D printing capabilities or an established enterprise seeking to enhance your production capabilities, understanding the nuances of different SLS printers will empower you to make informed choices that align with your objectives and budget.

Table of Contents

[Hide]

Understanding SLS Printing Technology and Its Applications for Businesses

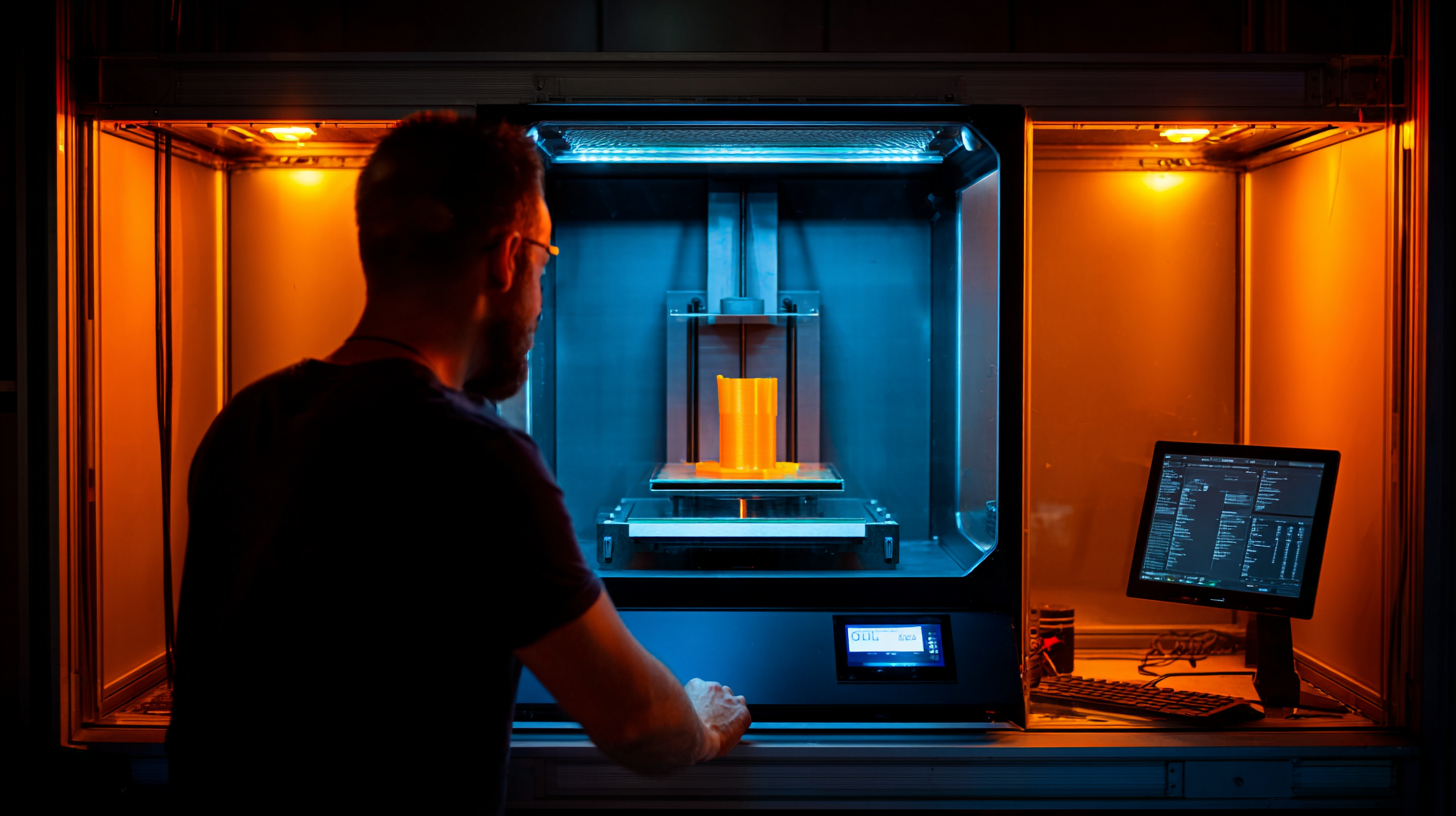

Understanding SLS printing technology is crucial for businesses looking to leverage additive manufacturing. SLS, or Selective Laser Sintering, utilizes a laser to fuse powdered materials, layer by layer, to create durable and complex geometries. According to a report by Markets and Markets, the global 3D printing materials market is projected to reach $3.7 billion by 2024, with SLS materials such as nylon and polyamide leading the charge due to their strength and flexibility.

The applications of SLS printing span various industries, from aerospace to healthcare. A study by Wohlers Associates indicates that over 35% of 3D printing applications involve industrial parts production, where SLS technology excels due to its ability to produce functional prototypes and end-use parts with high precision. This versatility allows companies not only to streamline production processes but also to reduce material waste, an essential factor given that the global push for sustainability in manufacturing is on the rise. Organizations employing SLS can expect to see significant reductions in lead times, enhancing their competitive edge in an increasingly demanding market.

Key Factors to Consider When Selecting an SLS Printer

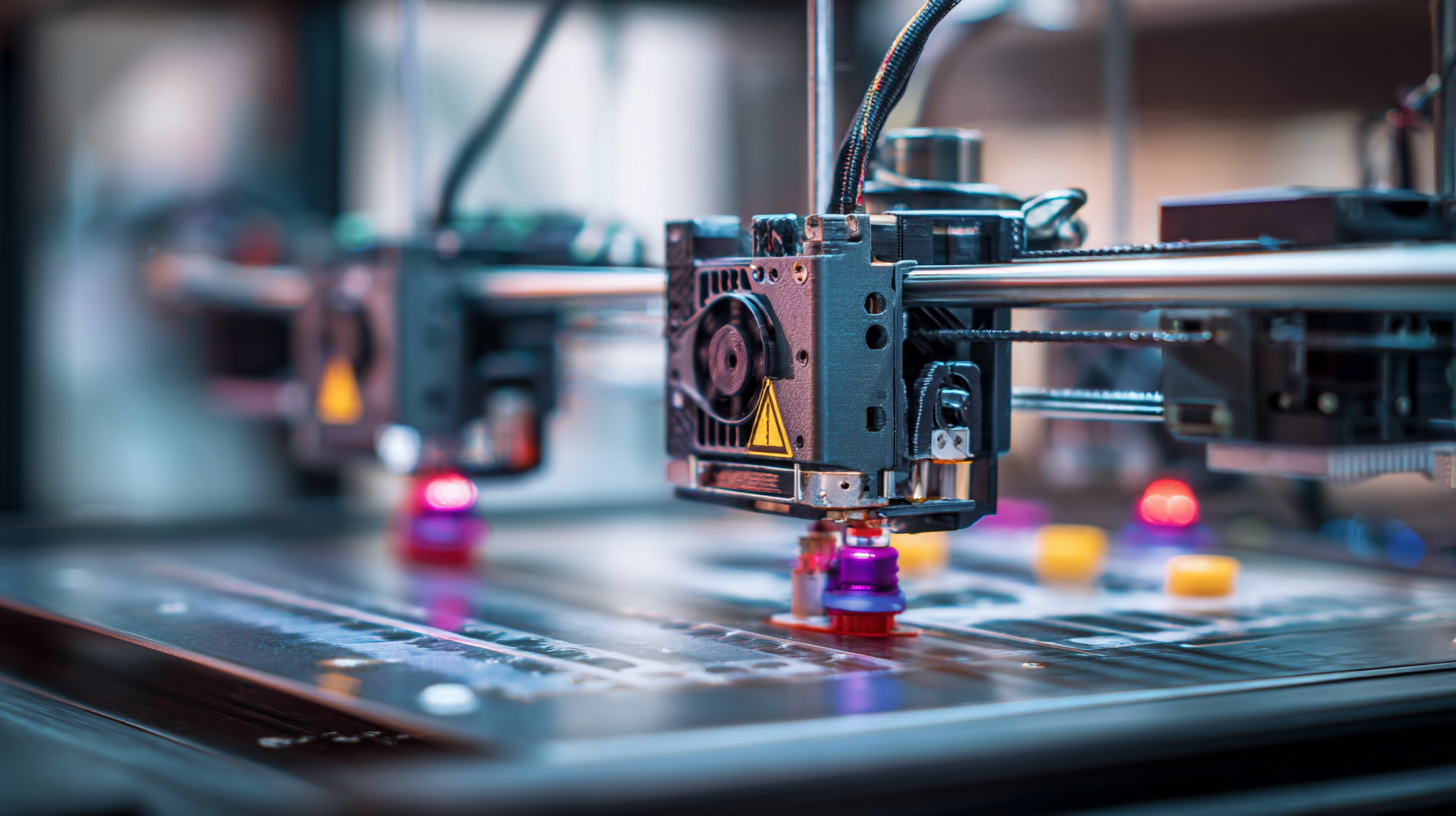

When selecting the right SLS printer for your business, several key factors must be considered to ensure you make the most informed decision. First, it is essential to evaluate the specific requirements of your projects, including the size and complexity of the parts you intend to produce. Different SLS printers offer varying build volumes and capabilities, which can significantly impact your production processes. Additionally, consider the materials compatible with the printer. The recent surge in polymer powder consumption highlights the importance of selecting machines that can handle diverse and high-quality materials.

Another critical aspect is the total cost of ownership, which encompasses not only the initial investment but also ongoing operational expenses like maintenance and material costs. With the SLS 3D printing market projected to grow from $1.353 billion in 2023 to $2.8118 billion by 2032, evaluating the long-term return on investment becomes crucial. Finally, don't overlook customer support and community engagement; a robust support system can enhance your user experience and provide you with valuable insights as you integrate SLS technology into your workflow.

Comparing Leading SLS Printer Brands and Their Features

When selecting an SLS printer for your business, it's crucial to compare leading brands and their unique features to find the best fit for your needs. Companies like EOS, 3D Systems, and Sinterit have established themselves as front-runners in the SLS market. EOS printers are known for their robust materials and scalability, making them ideal for larger manufacturing environments. Their software integration allows for seamless workflow management, which can significantly enhance productivity.

On the other hand, 3D Systems offers a range of SLS printers that cater to both small businesses and large enterprises. Their machines are lauded for precision and reliability, particularly in producing complex geometries. Additionally, 3D Systems focuses on advanced materials that can cater to various industries, from aerospace to medical applications. In contrast, Sinterit provides compact and user-friendly SLS solutions suitable for startups and smaller operations, emphasizing affordability without compromising quality. By carefully evaluating these features and capabilities, you can strategically align your choice of SLS printer with your business objectives.

Calculating Costs and ROI: Budgeting for Your SLS Printer Investment

Investing in an SLS printer requires a comprehensive evaluation of costs and potential returns on investment (ROI). A recent report from an industry leader indicates that while the initial purchase price of an SLS printer can range from $50,000 to over $200,000, business owners must also account for ongoing expenses like materials, maintenance, and operational costs, which can add up to an additional 20-30% annually. Understanding these costs is vital for creating a realistic budget that aligns with your company's financial capabilities and growth objectives.

Furthermore, it's essential to analyze how SLS printing can drive profitability. A study revealed that companies implementing 3D printing technologies saw a 25-50% reduction in time-to-market for new products, which translates to faster revenue generation. Additionally, with advancements in materials and processes, businesses can achieve significant savings on prototyping and production costs, enhancing their overall ROI. When seeking approval for an SLS printer investment, presenting these data-driven insights can bolster your case, emphasizing not just the technology's value, but its long-term impact on the bottom line.

Evaluating Support and Maintenance Options for SLS Print Solutions

When considering an SLS printer for your business, evaluating support and maintenance options is crucial to ensure long-term success.

According to a market report by Smithers Pira, over 40% of companies face operational delays due to insufficient technical support.

Therefore, selecting a manufacturer that offers robust customer service is not just beneficial; it's essential.

Look for providers that offer comprehensive warranties, rapid response times, and readily available technical resources.

This level of support can significantly minimize downtime, allowing your business to maintain productivity.

When considering an SLS printer for your business, evaluating support and maintenance options is crucial to ensure long-term success.

According to a market report by Smithers Pira, over 40% of companies face operational delays due to insufficient technical support.

Therefore, selecting a manufacturer that offers robust customer service is not just beneficial; it's essential.

Look for providers that offer comprehensive warranties, rapid response times, and readily available technical resources.

This level of support can significantly minimize downtime, allowing your business to maintain productivity.

In addition to immediate support, consider the ongoing maintenance requirements of your SLS printer. A report from Wohlers Associates indicates that proper maintenance can increase printer lifespan by up to 30%. Regular upkeep ensures that your equipment operates at peak efficiency, which directly correlates to consistent print quality and cost-effectiveness. Investing in a machine that provides easy access to parts and has a proven history of reliability will save both time and money in the long run. Prioritizing support and maintenance not only safeguards your investment but also positions your business for sustained growth in the competitive landscape of additive manufacturing.

Related Posts

-

5 Reasons Why Desktop SLS Printers Are Revolutionizing Small Scale Manufacturing

-

Understanding the Impact of Sintering 3D Printers on Modern Manufacturing Efficiency

-

Challenges Faced by Businesses in Adopting Commercial 3D Printers

-

What is the Future of 3D Printing Machines in Global Manufacturing

-

Top Strategies for Maximizing Efficiency with Sintering 3D Printers

-

The Future of Creative Production with 3D Plastic Printers