How to Choose the Right Dental 3D Printer for Your Practice Needs

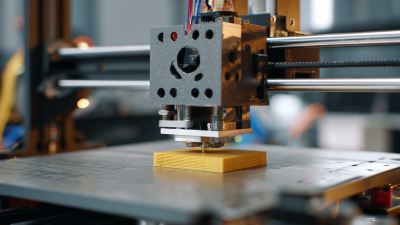

In today's rapidly evolving dental landscape, choosing the right dental 3D printer is crucial for practices aiming to enhance their efficiency and patient outcomes. With a variety of models and technologies available, dental professionals are faced with the challenge of selecting a printer that aligns with their specific operational needs, budget, and desired capabilities. This decision-making process not only impacts the workflow but also the quality of care provided to patients. Factors such as printing speed, material compatibility, and ease of use are integral to making an informed choice.

In this guide, we will explore key considerations and practical tips that will help you navigate the complex options available in the market, ensuring that your investment in a dental 3D printer will serve your practice effectively and enhance your commitment to providing top-notch dental services.

Table of Contents

[Hide]

Identify Your Practice's Specific 3D Printing Requirements and Goals

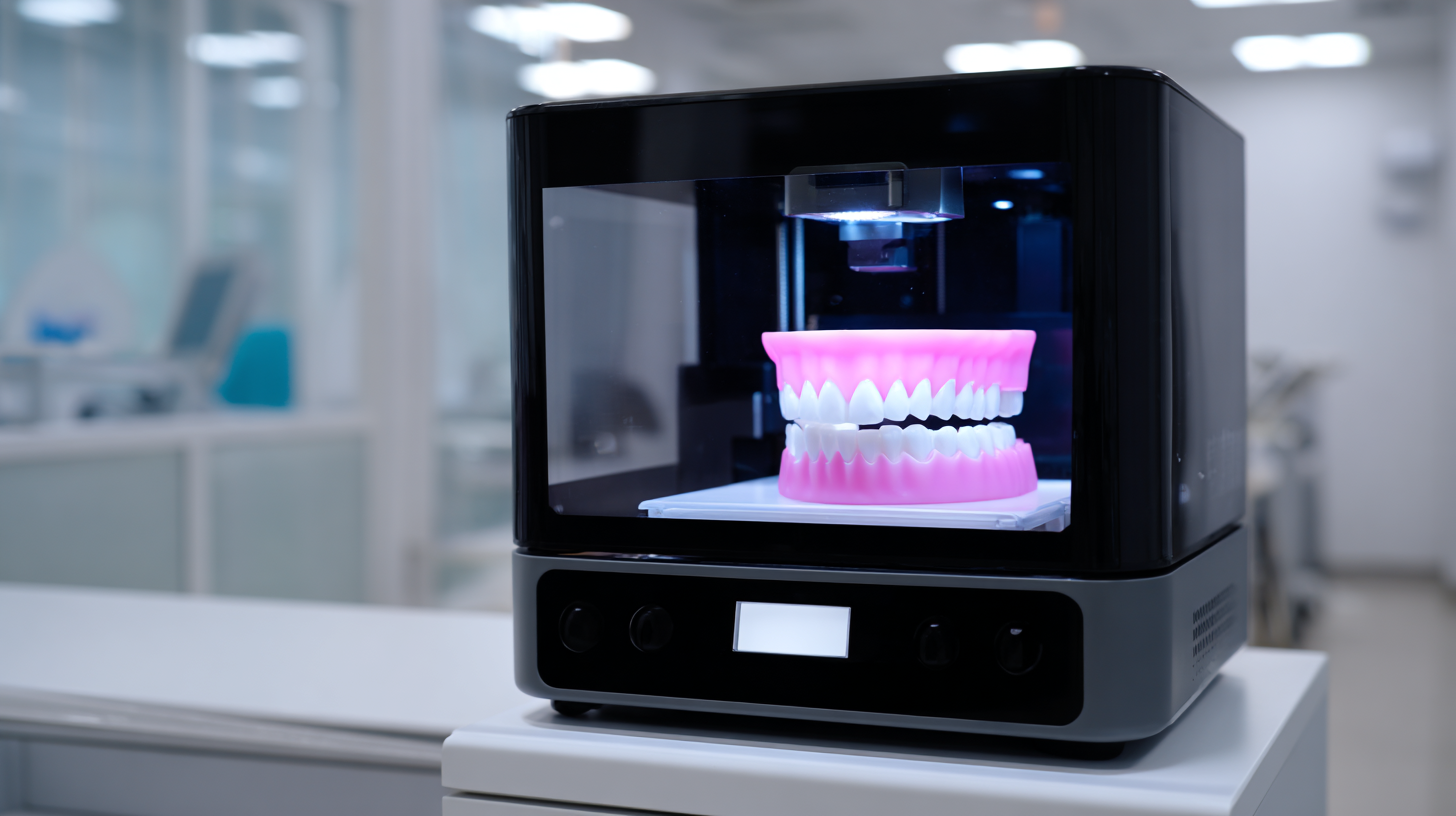

When selecting a dental 3D printer, it’s crucial to first identify the specific requirements and goals of your practice. Consider whether you primarily need the printer for creating models, surgical guides, or even orthodontic applications. Each of these uses has different demands in terms of precision, materials, and what features the printer must boast. For example, if your focus is on producing high-quality dental models, you may prioritize a printer with a high resolution and compatible resin types that offer excellent surface finishes.

When selecting a dental 3D printer, it’s crucial to first identify the specific requirements and goals of your practice. Consider whether you primarily need the printer for creating models, surgical guides, or even orthodontic applications. Each of these uses has different demands in terms of precision, materials, and what features the printer must boast. For example, if your focus is on producing high-quality dental models, you may prioritize a printer with a high resolution and compatible resin types that offer excellent surface finishes.

Additionally, evaluate the volume of work your practice handles. If you anticipate a high turnover of printed objects, opt for a 3D printer that can sustain prolonged use and has a faster printing speed. Integration capabilities with existing software and workflows are also essential. Choose a printer that can seamlessly fit into your current processes, thereby enhancing your productivity without requiring significant changes to your operations. By carefully assessing these factors, you can ensure that the 3D printer you select will effectively meet your specific practice needs and elevate your dental care offerings.

Evaluate Key Features of Dental 3D Printers for Optimal Performance

When selecting a dental 3D printer, it's crucial to evaluate key features that align with your practice needs to ensure optimal performance. According to a report by ResearchAndMarkets, the dental 3D printing market is expected to grow significantly, reaching a value of $6.5 billion by 2026. This growth highlights the increasing demand for precision and efficiency in dental practices, making the choice of a 3D printer more important than ever.

One of the primary considerations should be print resolution. Higher resolution printers deliver more detailed models, which can improve the fit and accuracy of dental restorations. Look for printers with a layer thickness of 25 microns or less for optimal results. Additionally, consider the materials compatibility; the ability to use various resins and plastics will enable your practice to expand its offerings, from surgical guides to orthodontic models.

**Tip:** Always assess the printer's speed and productivity, particularly if your practice handles a high volume of cases. Faster print times can result in quicker turnaround for patients, enhancing their overall experience.

Another key feature to evaluate is the software system. A user-friendly interface can significantly reduce the learning curve and improve workflow efficiency. As seen in trends reported by the International Journal of Dentistry, practices using integrated CAD/CAM systems alongside 3D printing systems see a 30% increase in productivity.

**Tip:** Ensure that the 3D printer’s software can easily integrate with your existing systems for streamlined operations.

Comparison of Key Features of Dental 3D Printers

Compare Material Options and Compatibility for Dental Applications

When selecting a dental 3D printer, understanding the material options and their compatibility for specific dental applications is crucial. Today's market offers a range of advanced 3D printing technologies, including SLA, DLP, and LCD printers, each with unique material compatibilities. For instance, polyurethane-based biomaterials are emerging as versatile options due to their high tensile strength and adaptability, making them suitable for various dental applications from temporary restorations to complex orthodontic devices.

Recent evaluations of dental materials have revealed significant advancements in their cytocompatibility and bonding performance. Studies show that 3D printed dental specimens exhibit superior cell adhesion, presenting better outcomes for temporary restorations than traditional methods. Furthermore, the color compatibility assessments between human enamel, dentine, and different ceramic systems suggest that practitioners can achieve more aesthetic results by choosing the right materials and technologies that ensure optimal integration and visual outcomes in dental restorations. As the industry evolves, keeping abreast of these developments will empower dental professionals to make informed decisions tailored to their specific practice needs.

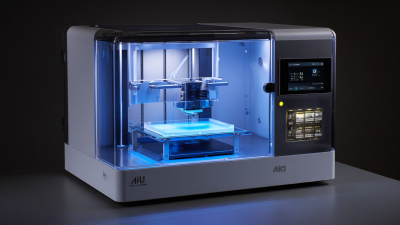

Consider Size, Speed, and Ease of Use for Efficient Workflow Integration

When selecting the right dental 3D printer for your practice, focusing on size, speed, and ease of use is crucial for efficient workflow integration. According to industry reports, dental practices that integrate 3D printing into their operations can reduce production time by up to 50% compared to traditional methods. This improvement in speed allows dentists to provide quicker service to their patients and enhances overall satisfaction.

Size is another essential consideration; a compact printer can fit into smaller workspaces while still delivering high-quality prints. The right size printer not only saves valuable office space but can also streamline processes, reducing the need for additional equipment and minimizing workflow disruptions. Additionally, ease of use is paramount—printers equipped with user-friendly interfaces and automated features allow staff to operate them with minimal training. Reports indicate that practices leveraging AI-driven automation experience higher productivity levels and lower operational costs, which ultimately contribute to a more efficient and effective dental service.

How to Choose the Right Dental 3D Printer for Your Practice Needs

| Printer Model | Size (mm) | Speed (mm/hr) | Ease of Use | Price ($) |

|---|---|---|---|---|

| Model A | 250 x 250 x 300 | 20 | High | 5,000 |

| Model B | 300 x 300 x 300 | 25 | Medium | 7,500 |

| Model C | 200 x 200 x 250 | 15 | Low | 3,000 |

| Model D | 250 x 250 x 400 | 30 | High | 8,000 |

Assess Budget Considerations and Long-Term Maintenance Costs

When selecting the right dental 3D printer for a practice, understanding budget considerations and long-term maintenance costs is crucial. Initial purchase prices can vary significantly depending on the printer's capabilities, such as resolution, speed, and material compatibility. It is essential to assess not only the upfront investment but also the potential expenses associated with maintenance, such as replacement parts, software updates, and materials over time. This foresight helps practices plan financially for the life cycle of the printer, ensuring that they can manage costs effectively.

Additionally, just as in other sectors where equipment impacts operational efficiency, dental practices should consider how 3D printing technology can improve productivity and patient care while avoiding hidden expenses. For instance, integrating a high-quality printer may lead to cost savings by reducing outsourcing needs and speeding up the workflow, potentially offsetting maintenance costs. By conceptualizing budget planning as an ongoing process rather than a one-time event, dental practices can make informed decisions that align with their financial health and operational goals.

Related Posts

-

How to Choose the Right SLS Printer for Your Business: A Data-Driven Guide

-

Unlocking the Future Best 8K 3D Printer for Global Buyers

-

The Future of Creative Production with 3D Plastic Printers

-

Understanding the Impact of Sintering 3D Printers on Modern Manufacturing Efficiency

-

Mastering the Basics of Powder 3D Printing with Our Step by Step Guide

-

Top Strategies for Maximizing Efficiency with Sintering 3D Printers