5 Reasons Why Desktop SLS Printers Are Revolutionizing Small Scale Manufacturing

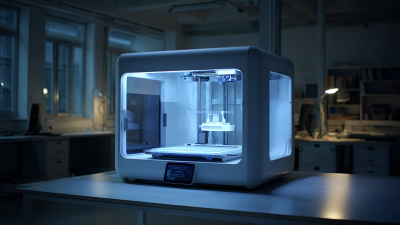

The advent of desktop SLS printers is transforming the landscape of small-scale manufacturing, offering unprecedented capabilities that were once reserved for large industrial operations. According to a report by SmarTech Analysis, the market for 3D printing is projected to reach $41 billion by 2027, with the adoption of Selective Laser Sintering (SLS) technology playing a pivotal role in this growth. As businesses seek cost-effective and efficient production methods, desktop SLS printers provide an accessible solution that meets the demands for rapid prototyping and customized production.

These printers enable manufacturers to achieve high-quality, intricate designs with reduced material waste, contributing to a more sustainable production cycle. With the ability to produce functional parts on-demand, desktop SLS printers are not only enhancing design flexibility but also driving innovation in industries ranging from automotive to consumer goods, solidifying their place as essential tools for modern manufacturing.

Table of Contents

[Hide]

Benefits of Desktop SLS Printers for Small Batch Production

Desktop SLS (Selective Laser Sintering) printers are transforming small batch production by offering an array of benefits that enhance efficiency and creativity. One of the most significant advantages is their ability to create complex geometries without the limitations often found in traditional manufacturing methods. This capability allows designers and engineers to produce intricate parts that were previously impossible to manufacture, thus opening new avenues for innovation in product development.

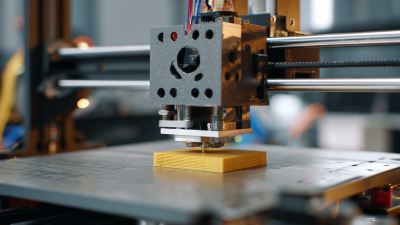

Another key benefit of desktop SLS printers is the reduction in material waste. Unlike subtractive manufacturing processes that cut away excess material, SLS technology uses powdered materials that are only sintered where needed. As a result, businesses can optimize their material usage, leading to lower costs and a more environmentally friendly production process. Moreover, the ability to print multiple parts simultaneously means that companies can achieve higher output in less time, making these printers a perfect fit for small-scale manufacturing environments looking to maximize efficiency.

Key Features of SLS Technology That Enhance Manufacturing Efficiency

The technological advancements in Selective Laser Sintering (SLS) printers are significantly enhancing small-scale manufacturing processes. One of the key features of SLS technology is its ability to produce complex geometries without the need for support structures, which not only reduces material waste but also accelerates the design iteration process. This efficiency is crucial for small manufacturers who often operate with limited budgets and timeframes.

Another notable aspect of SLS printers is their ability to work with a wide variety of materials, including polymers and metals, which broadens the application range for small-scale production. According to industry reports, the SLS 3D printing market is projected to reach a value of $2.8118 billion by 2032, up from $1.353 billion in 2023, reflecting a robust compound annual growth rate of 8.5%. This growth underscores the increasing demand for efficient, scalable manufacturing solutions that SLS technology uniquely provides, enabling smaller manufacturers to compete more effectively in a rapidly evolving marketplace.

Cost-Effectiveness of Desktop SLS Printers in Small Scale Operations

Desktop selective laser sintering (SLS) printers are reshaping the landscape of small-scale manufacturing, particularly due to their cost-effectiveness. These printers offer an affordable entry point for businesses to adopt advanced manufacturing techniques that were once only accessible to larger enterprises. By utilizing powdered materials to produce high-quality prototypes and functional parts, desktop SLS printers help reduce material waste and lower production costs, making them an attractive option for startups and small manufacturers looking to innovate without breaking the bank.

In the realm of aerospace 3D printing, the advantages of desktop SLS technology become even more pronounced. The ability to produce intricate and lightweight components from polymers allows for rapid prototyping and the efficient creation of customized parts tailored to specific applications. As the aerospace industry continues to embrace additive manufacturing, small-scale operations equipped with desktop SLS printers can compete effectively against larger manufacturers, thus democratizing access to advanced aerospace solutions. The synergy between affordability and cutting-edge technology is paving the way for a new era in manufacturing, where even the smallest players can contribute to industry advancements.

5 Reasons Why Desktop SLS Printers Are Revolutionizing Small Scale Manufacturing - Cost-Effectiveness of Desktop SLS Printers in Small Scale Operations

| Reason | Description | Cost Savings (%) | Time Reduction (hrs) | Material Versatility |

|---|---|---|---|---|

| Affordable Initial Investment | Lower cost compared to industrial SLS systems. | 30% | N/A | Limited to specific materials |

| Reduced Production Costs | Lower material waste with efficient printing. | 25% | 5 hrs | Multiple materials |

| Lower Labor Costs | Less manual post-processing required. | 20% | 3 hrs | Specialized filaments |

| Efficient Prototyping | Quick iteration reduces design time and costs. | 15% | 2 hrs | Wide range of plastic materials |

| Lower Maintenance Costs | Fewer parts and easier service compared to larger units. | 10% | N/A | Compatible with various feedstock |

Customization and Design Flexibility Offered by SLS Printing

The advent of Desktop SLS (Selective Laser Sintering) printers is reshaping the landscape of small-scale manufacturing. One of the most significant advantages lies in the customization and design flexibility they provide. Unlike traditional manufacturing methods that often require extensive tooling and molds, SLS printing allows designers to create intricate, tailored components without additional costs for each variation. This adaptability makes it possible for businesses to respond swiftly to market demands and innovate continuously.

When utilizing SLS printing, consider the following tips for maximizing your design potential. First, embrace complex geometries; SLS is uniquely suited for creating parts with elaborate shapes and internal features that would be impossible to produce using conventional methods. Second, keep in mind material properties when designing. SLS supports a variety of materials, each with distinct characteristics, so selecting the right one can enhance your part's performance and longevity.

Moreover, efficient design reduces waste and saves costs. By optimizing your parts for additive manufacturing, you can minimize material usage while still achieving high strength and durability. This design philosophy not only lowers production costs but also aligns with sustainable practices, making it a winning strategy for small-scale manufacturers seeking to innovate and grow.

Impact of SLS Printers on Speed and Turnaround Times in Production

Desktop SLS (Selective Laser Sintering) printers are transforming small-scale manufacturing by significantly improving speed and turnaround times in production. According to a recent report by Smithers Pira, SLS technology can reduce production time by up to 75% compared to traditional manufacturing methods. This accelerated process is particularly beneficial for small businesses, allowing them to quickly iterate on designs and respond to market demands without the lengthy delays often associated with conventional manufacturing workflows.

Moreover, desktop SLS printers enable the production of complex geometries that were previously challenging or impossible to achieve with other techniques, such as injection molding. Global Market Insights projects that the SLS 3D printing market will grow at a compound annual growth rate (CAGR) of 22% from 2021 to 2027, reflecting the increasing reliance on this technology for rapid prototyping and small-batch production. The ability to produce functional parts on demand not only shortens lead times but also minimizes inventory costs, further enhancing operational efficiency for manufacturers who embrace this innovative approach.

Impact of SLS Printers on Speed and Turnaround Times in Production

Related Posts

-

Comprehensive Guide to Choosing the Best SLA Printers for Your Business Needs

-

The Future of Creative Production with 3D Plastic Printers

-

Innovative Solutions for Enhancing Production with Powder 3D Printers

-

Understanding the Impact of Sintering 3D Printers on Modern Manufacturing Efficiency

-

Challenges Faced by Businesses in Adopting Commercial 3D Printers