Digital Revolution Best 3D Printers That Print Metal Transforming Manufacturing Efficiency

The advent of 3D printing technology has ushered in a digital revolution, significantly transforming manufacturing processes across various industries. Among the most notable advancements are **3D printers that print metal**, which have gained considerable traction in recent years. According to a report by MarketsandMarkets, the metal 3D printing market is projected to grow from $0.6 billion in 2021 to $3.5 billion by 2026, representing a staggering compound annual growth rate (CAGR) of 42.6%. This rapid expansion underscores the growing demand for innovative manufacturing solutions that enhance efficiency while reducing material waste. By leveraging metal 3D printing, companies can produce complex geometries with unprecedented speed and precision, enabling them to meet the challenges of modern production requirements. As we explore the best 3D printers that print metal, we will delve into how these cutting-edge machines are redefining the landscape of manufacturing efficiency.

Table of Contents

[Hide]

Emergence of Metal 3D Printing in the Digital Revolution

The emergence of metal 3D printing has significantly influenced manufacturing efficiency, playing a crucial role in the broader context of the Digital Revolution. According to a report by SmarTech Analysis, the metal additive manufacturing market is projected to reach $6.5 billion by 2026, showcasing a compound annual growth rate (CAGR) of over 30%. This rapid growth highlights the increasing adoption of metal 3D printing technologies across various industries, including aerospace, automotive, and healthcare, where precision and customization are paramount.

Metal 3D printing technology allows for the production of complex geometries that were previously challenging or impossible to achieve with traditional manufacturing methods. For instance, GE Aviation has demonstrated that using additive manufacturing can reduce the weight of components by up to 70%, leading to significant cost savings and improved fuel efficiency for jet engines. Additionally, a study by Wohlers Associates suggests that metal 3D printing can decrease production times by as much as 50%, further enhancing operational efficiencies and allowing companies to respond quickly to market demands. As these technologies continue to evolve, they are fundamentally transforming the landscape of modern manufacturing, driving innovation and competitiveness in the global supply chain.

Key Features of Top Metal 3D Printers Enhancing Manufacturing Efficiency

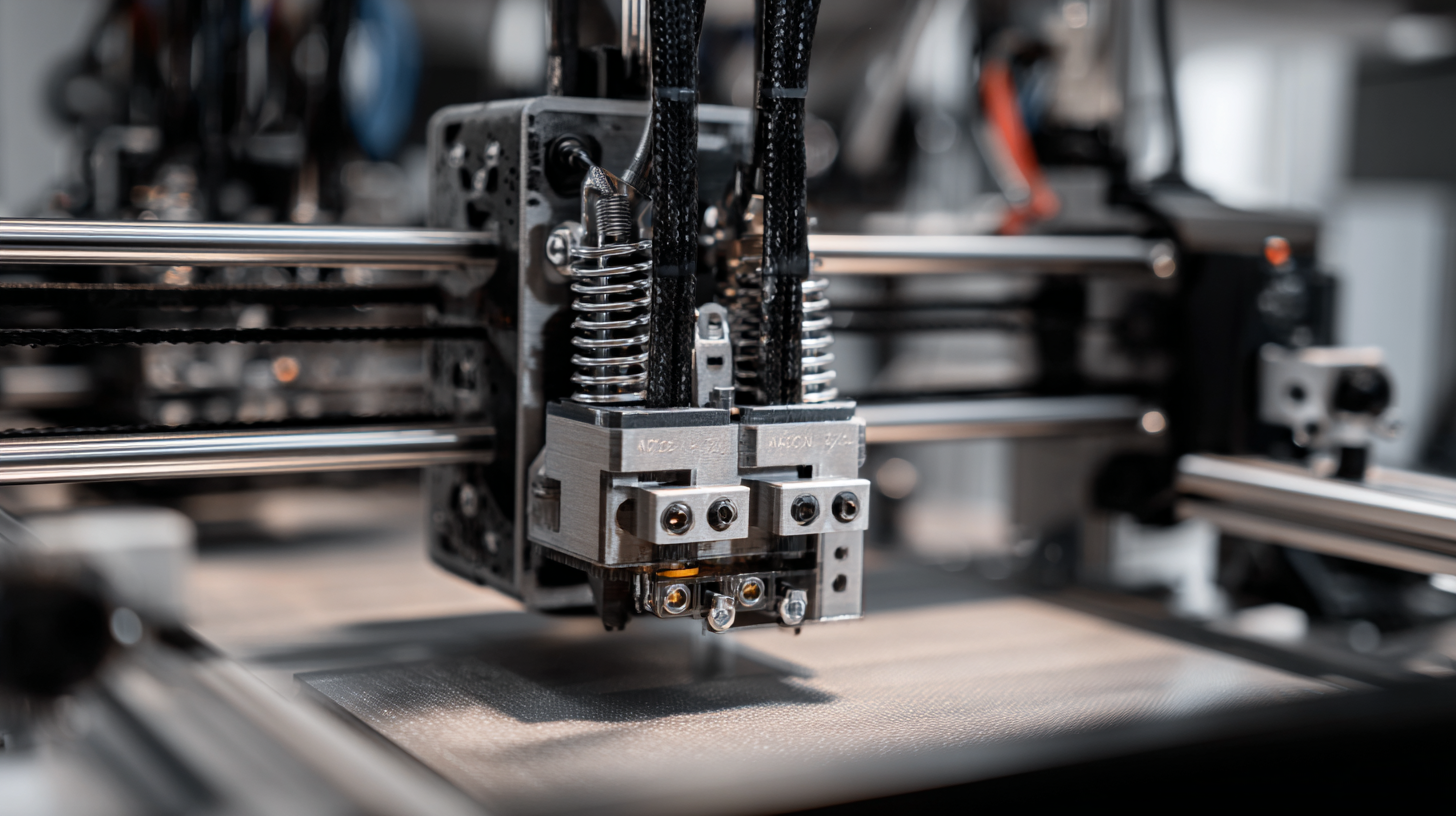

The digital revolution has fundamentally transformed manufacturing, with metal 3D printers at the forefront. These state-of-the-art machines offer key features that significantly enhance manufacturing efficiency. For instance, technologies such as Selective Laser Melting (SLM) and Electron Beam Melting (EBM) permit intricate designs that are often impossible to achieve with traditional methods. According to a report by Deloitte, the adoption of additive manufacturing can lead to a reduction of lead times by up to 90%, enabling faster production cycles and more agile manufacturing processes.

In addition to speed, the precision and material versatility of the best metal 3D printers contribute greatly to operational efficiency. Leading machines can produce parts with tolerances as tight as 0.1 mm, minimizing waste and reducing the need for costly rework. A study by Wohlers Associates highlights that the metal 3D printing market is expected to grow at a CAGR of over 30% from 2021 to 2026, underlining the technology's growing importance in sectors such as aerospace and automotive. As manufacturers continue to capitalize on these advancements, the potential for cost savings and productivity improvements remains substantial, fostering innovation across industries.

Digital Revolution Best 3D Printers That Print Metal Transforming Manufacturing Efficiency - Key Features of Top Metal 3D Printers Enhancing Manufacturing Efficiency

| Printer Model | Layer Thickness (mm) | Build Volume (cm³) | Material Compatibility | Max Temperature (°C) | Speed (cm³/hr) | Features |

|---|---|---|---|---|---|---|

| Model A | 0.1 | 4500 | Stainless Steel, Aluminum | 300 | 100 | High Precision, Multi-Material |

| Model B | 0.05 | 3000 | Titanium, Copper | 280 | 80 | Fast Layering, Automated Calibration |

| Model C | 0.08 | 5000 | Nickel Alloys, Stainless Steel | 320 | 120 | Energy Efficient, Modular Design |

| Model D | 0.15 | 4000 | Aluminum, Steel Alloys | 250 | 90 | User-Friendly Interface, Quick Setup |

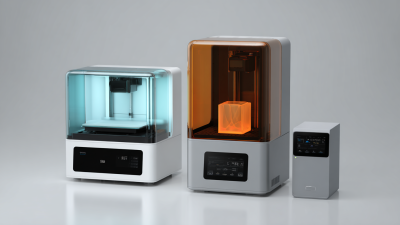

Comparative Analysis of Leading Metal 3D Printer Models

The landscape of metal 3D printing is rapidly evolving, offering transformative benefits for manufacturing efficiency. A comparative analysis of leading models in this sector highlights the advances in Direct Metal Laser Sintering (DMLS) technology, which have demonstrated significant improvements in process parameters that affect geometric accuracy and reduce relative errors. Reports indicate that optimizing gas circulation within these printers is crucial for enhancing the quality of printed parts, a finding supported by recent studies on performance factors in metal 3D systems.

In addition to DMLS, emerging techniques such as vat photopolymerization and material extrusion are gaining traction. These methods have shown promising results in producing complex lightweight structures, as observed in the recent study on compound gears for extruder machines, where variations in process parameters led to discernible impacts on accuracy. As reported in a comprehensive market analysis, the projected growth of the 3D printing sector over the next decade will be driven by innovations in material types—from everyday thermoplastics to high-performance polymers—allowing manufacturers to meet diverse application needs effectively.

Real-World Applications of Metal 3D Printing in Various Industries

Metal 3D printing has emerged as a game-changing technology in various industries, allowing for the production of complex geometries that were previously impossible with traditional manufacturing methods. According to a report by Wohlers Associates, the metal 3D printing market is projected to reach $9.0 billion by 2028, demonstrating a compound annual growth rate (CAGR) of 24.8% from 2021 to 2028. This growth reflects the widespread adoption of metal additive manufacturing in industries such as aerospace, automotive, and medical, where precision and efficiency are paramount.

In the aerospace sector, companies like Boeing and Airbus are utilizing metal 3D printing to produce lightweight components that enhance fuel efficiency. For instance, Boeing has reported weight savings of up to 75% on certain parts, translating to significant long-term cost reductions. Similarly, in the medical field, custom implants and surgical tools are being manufactured using this technology, enabling personalized patient care. Medical device manufacturers have found that metal 3D printing reduces lead times by up to 50%, allowing them to respond quickly to market demands.

**Tips**: When considering metal 3D printing for your business, evaluate the specific needs of your industry to identify potential applications. Collaborating with a knowledgeable vendor can also provide insights into material selection and design optimization. Furthermore, investing in training for your team will facilitate the smooth integration of this technology into your manufacturing processes.

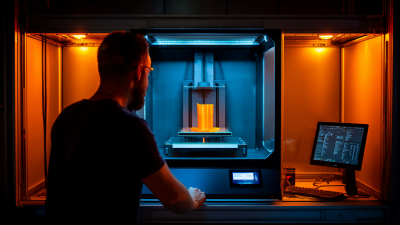

Future Trends in Metal 3D Printing Technology and Manufacturing

The future of metal 3D printing technology is poised to redefine manufacturing efficiency across various industries. With advances in materials and printing methods, companies are increasingly turning to metal additive manufacturing for producing spare parts, prototypes, and even complex components in sectors such as automotive and aerospace. This shift not only enhances precision but also significantly reduces lead times and production costs, making it a game-changer for manufacturers looking to stay competitive.

Tips for optimizing metal 3D printing processes include investing in advanced materials that can provide superior performance and reliability. Furthermore, exploring multi-material additive manufacturing approaches can yield innovative designs and applications, giving companies an edge in product development. It is essential for businesses to stay informed on the latest trends and technologies in this rapidly evolving field to fully harness its potential.

As we look ahead to 2030, the integration of metal 3D printing into mainstream manufacturing practices is expected to accelerate. The industry's value is predicted to exceed $40 billion, driven by the demand for customization, efficiency, and sustainability. Embracing these technologies can not only improve production capabilities but also pave the way for groundbreaking innovations in product design and functionality.

Future Trends in Metal 3D Printing Technology

This chart illustrates the projected growth in the adoption of metal 3D printing technologies over the next five years, highlighting the increasing efficiency and capabilities in various manufacturing sectors.

Related Posts

-

How to Choose the Right SLS Printer for Your Business: A Data-Driven Guide

-

Challenges Faced by Businesses in Adopting Commercial 3D Printers

-

How to Choose the Right Dental 3D Printer for Your Practice Needs

-

What is the Future of 3D Printing Machines in Global Manufacturing

-

Mastering the Basics of Powder 3D Printing with Our Step by Step Guide

-

The Future of Creative Production with 3D Plastic Printers