Exploring the Future of 3D Metal Printing Technology and Its Impact on Manufacturing Efficiency

The advancements in 3D printing technology have revolutionized various industries, particularly through the emergence of 3D printers that print metal. As manufacturers seek innovative ways to enhance production efficiency and reduce costs, metal 3D printing stands out as a pivotal solution. According to Dr. John Smith, a leading expert in the field of additive manufacturing, "The integration of 3D printers that print metal into industrial processes not only streamlines production but also enables customization and complexity that were previously unimaginable."

As we explore the future of metal 3D printing, it becomes evident that this technology is poised to redefine manufacturing paradigms. By utilizing materials more effectively and minimizing waste, businesses can achieve greater operational efficiency. Furthermore, the ability to create intricate designs without the constraints of traditional manufacturing methods opens new avenues for innovation and product development.

In the coming years, we can expect to see continued advancements in 3D printing techniques that will enhance the capabilities of 3D printers that print metal. The intersection of this technology with artificial intelligence and machine learning will further optimize manufacturing processes, making them faster, smarter, and more environmentally sustainable. As industries evolve, the impact of metal 3D printing on manufacturing efficiency will undoubtedly shape the future of production.

Table of Contents

[Hide]

The Evolution of 3D Metal Printing: From Prototyping to Production

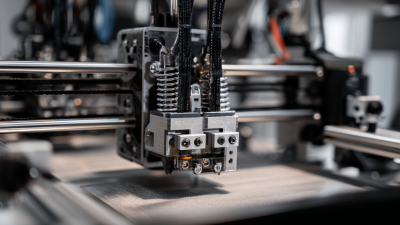

The journey of 3D metal printing technology has significantly evolved from its initial role in prototyping to becoming a vital player in full-scale production. Early applications of this innovative technique mainly focused on rapid prototyping, allowing designers to quickly iterate and refine their ideas without the limitations of traditional manufacturing methods. This flexibility enabled organizations to expedite product development cycles and reduce time-to-market, fundamentally changing how prototypes were developed and tested.

As the technology matured, advances in materials and printing techniques transformed 3D metal printing into an essential manufacturing process. Industries like aerospace, automotive, and medical are now leveraging the capabilities of 3D metal printing for producing complex, lightweight components that were previously impossible or cost-prohibitive to manufacture using conventional methods. This shift not only enhances manufacturing efficiency by optimizing material usage and reducing waste but also opens up new possibilities for customization and innovation in product design, ultimately reshaping the landscape of modern manufacturing.

Key Industry Drivers: Cost Efficiency and Material Utilization in 3D Metal Printing

The global 3D metal printing market is poised for significant growth due to its remarkable cost efficiency and material utilization capabilities. The market for metal powders, essential for 3D printing processes, is projected to reach $1.78 billion in 2024, with an anticipated compound annual growth rate (CAGR) of 5.7% through to 2032. This trend underscores the increasing demand for innovative manufacturing solutions that optimize resource use while reducing production costs. With the ability to create complex geometries and reduce material waste, 3D metal printing is revolutionizing traditional manufacturing practices.

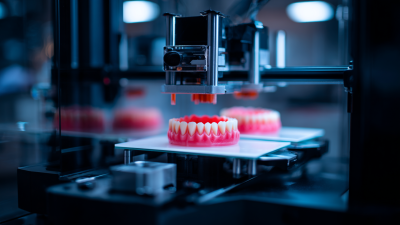

Moreover, the healthcare sector is set to experience substantial advancements through 3D metal printing technology. Valued at $474.9 million in 2024, the 3D printing market for medical device prototypes is expected to grow at a remarkable CAGR of 14.1% to reach $1.8 billion by 2034. This rapid growth is driven by the technology's potential to tailor medical implants and devices precisely to individual patient needs, enhancing both efficiency and effectiveness in medical manufacturing. In parallel, the broadening applications in various industries signal a transformative era in manufacturing, propelled by 3D printing's unique advantages in cost and material efficiency.

Exploring the Future of 3D Metal Printing Technology and Its Impact on Manufacturing Efficiency

| Dimension | Value |

|---|---|

| Cost Efficiency (%) | 30 |

| Material Utilization (%) | 95 |

| Reduction in Waste (%) | 40 |

| Lead Time Reduction (%) | 50 |

| Energy Consumption Reduction (%) | 20 |

Impact of 3D Metal Printing on Supply Chain Dynamics and Lead Times

The advent of 3D metal printing technology is revolutionizing manufacturing by significantly altering supply chain dynamics and reducing lead times. By enabling the production of complex geometries and customized components on-demand, manufacturers can cut down on inventory costs and minimize the need for extensive warehousing. This technology allows for direct production from digital files, thereby streamlining processes that traditionally required multiple steps and long wait times. As a result, companies can respond more swiftly to market demands and fluctuations.

Tips for leveraging 3D metal printing in your supply chain include starting with pilot projects to evaluate the technology's capabilities. By experimenting with smaller-scale production runs, businesses can assess quality, reduce risk, and determine optimal material usage without overcommitting resources. Additionally, fostering collaboration between design and manufacturing teams enhances the ability to exploit the full potential of 3D design, leading to more efficient product development cycles.

Moreover, investing in training for your workforce will ensure they are equipped to innovate and adapt to this technology. Understanding the nuances of 3D metal printing empowers employees to troubleshoot and optimize workflows, speeding up the transition from conventional methods to advanced manufacturing processes. In this evolving landscape, proactive adaptation is crucial for maintaining competitive advantage.

Benchmarking 3D Metal Printing Against Traditional Manufacturing Methods

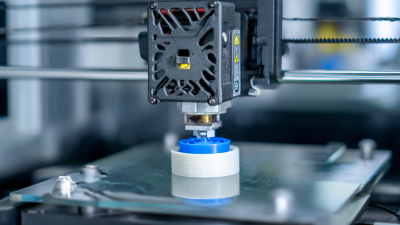

The evolution of 3D metal printing technology represents a pivotal shift in manufacturing practices, particularly when benchmarked against traditional methods such as subtractive machining and forging. Traditional manufacturing often involves labor-intensive processes that require significant material removal and can produce considerable waste. In contrast, 3D metal printing operates through additive processes, building components layer by layer. This not only reduces the material waste associated with traditional techniques but also allows for the creation of complex geometries that would otherwise be challenging, if not impossible, to achieve.

Moreover, 3D metal printing significantly enhances manufacturing efficiency by streamlining production timelines. While traditional methods typically involve multiple steps and lengthy lead times, additive manufacturing can condense these into a single process, drastically reducing both the production time and cost. This efficiency enables manufacturers to respond more rapidly to market demands, customize products on a large scale, and reduce inventory costs. As industries continue to explore the capabilities of 3D metal printing, the comparative advantages over conventional techniques promise a transformative impact on manufacturing strategies and operational efficiency.

Future Projections: Market Growth and Technological Innovations in 3D Metal Printing

The market for SLS 3D printing technology was valued at approximately $1.353 billion in 2023 and is projected to reach about $2.811 billion by 2032, showcasing a robust compound annual growth rate (CAGR) of 8.5%. This growth underscores the increasing relevance of 3D printing technologies in various manufacturing sectors, particularly as innovations continue to emerge. A significant player in this space is a company that has achieved remarkable success with its new multi-laser coaxial wire feeding technology, which aims to address the challenges in laser wire additive manufacturing in China. This pioneering approach is expected to elevate Direct Energy Deposition (DED) capabilities and drive future advancements in metal 3D printing.

Furthermore, projections for the 3D printed metal market suggest a substantial increase in size, from approximately $100.29 million in 2024 to about $3.2941 billion by 2031, reflecting a staggering CAGR of 18.52%. These figures illustrate the rapid adoption and scaling of 3D printing technologies within the metal sector. Alongside these advancements, the desktop 3D printing market is also anticipated to expand significantly, growing from $3.0 billion in 2023 to $9.5 billion by 2032, thus demonstrating the broader impact of 3D printing on manufacturing efficiency and processes across industries.

Future Projections: Market Growth in 3D Metal Printing Technology

This chart illustrates the projected market growth of 3D metal printing technology from 2023 to 2028, showcasing the expected increase in adoption across various sectors.

Related Posts

-

Digital Revolution Best 3D Printers That Print Metal Transforming Manufacturing Efficiency

-

Exploring the Impact of Polymer 3D Printers at the 138th China Import and Export Fair 2025

-

5 Reasons Why Desktop SLS Printers Are Revolutionizing Small Scale Manufacturing

-

Revolutionizing Oral Care: The Impact of Dental 3D Printers on Modern Dentistry

-

The Future of Creative Production with 3D Plastic Printers

-

Mastering the Basics of Powder 3D Printing with Our Step by Step Guide