What is the Future of 3D Printing Machines in Global Manufacturing

The future of 3D printing machines in global manufacturing is poised for transformative growth, driven by advancements in technology and increasing adoption across various industries. According to a report by MarketsandMarkets, the 3D printing market is expected to reach $34.85 billion by 2024, growing at a compound annual growth rate (CAGR) of 25.76% from 2019. This rapid expansion highlights the crucial role that 3D printing machines will play in enhancing production efficiency, reducing waste, and enabling more sustainable manufacturing practices. As industries explore innovative applications—from aerospace and automotive to healthcare and consumer goods—the capabilities of 3D printing machines are redefining traditional manufacturing processes. With ongoing investments in research and development, the potential for customized solutions and localized production is becoming increasingly realistic, promising a future where 3D printing technology is central to the global manufacturing landscape.

Table of Contents

[Hide]

The Evolution of 3D Printing Technology in Manufacturing Processes

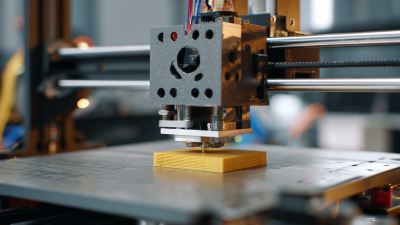

The evolution of 3D printing technology in manufacturing processes has been nothing short of revolutionary. Initially seen as a niche tool for prototyping, 3D printing has transitioned into a core component of modern manufacturing, enabling companies to produce complex geometries that traditional methods struggle to achieve. With advancements in materials and printing techniques, industries from aerospace to healthcare are leveraging these capabilities to create lightweight components, customized prosthetics, and even bioprinted tissues. This shift not only enhances design flexibility but also reduces material waste, making manufacturing processes more sustainable.

As we look to the future, the integration of artificial intelligence and machine learning into 3D printing systems will further streamline production efficiencies. Predictive analytics will enable manufacturers to optimize print settings in real time, minimizing downtime and maximizing output. Additionally, the advent of multi-material printing will expand possibilities, allowing for the creation of intricate assemblies in a single build process. This innovation could lead to a paradigm shift where the traditional assembly line is disrupted, giving way to localized, on-demand manufacturing solutions that are tailored to specific consumer needs, ultimately reshaping the landscape of global manufacturing as we know it.

Transformative Applications of 3D Printing in Various Industries

The transformative applications of 3D printing in various industries are reshaping the landscape of global manufacturing. According to a 2022 report by Wohlers Associates, the 3D printing industry is projected to reach $40.9 billion by 2026, reflecting an annual growth rate of 23.5%. This rapid expansion is largely attributed to the technology's ability to streamline production processes, reduce waste, and enable the customization of products at scale.

In the aerospace industry, 3D printing is revolutionizing the way aircraft components are produced. A 2023 study by Deloitte highlighted that by employing additive manufacturing, companies can significantly cut costs and lead times, with some reports suggesting reductions of up to 70% in production time for complex parts.

Similarly, in the healthcare sector, 3D printing is facilitating the creation of tailored medical devices and prosthetics, enhancing patient outcomes. The market for 3D-printed medical tools is anticipated to surge, with a projected compound annual growth rate of 18.3% through 2028, as stated in a recent publication by Grand View Research. These advancements underscore the pivotal role of 3D printing in driving innovation and efficiency across multiple sectors.

Challenges Facing 3D Printing Adoption in Global Markets

The adoption of 3D printing in global manufacturing faces several significant challenges that hinder its widespread implementation. According to a report by Wohlers Associates, the global 3D printing market is projected to grow from $12.6 billion in 2020 to over $35 billion by 2026. Despite this promising outlook, the pace of adoption remains slow, primarily due to high costs associated with advanced 3D printing machines and materials. Many manufacturers are still grappling with the initial investment required to integrate these technologies into their existing production lines.

Additionally, there are concerns regarding the scalability and reliability of 3D printing processes. A study published by the International Journal of Advanced Manufacturing Technology highlights that while 3D printing offers immense flexibility in prototyping, issues like print quality and speed can vary significantly, affecting mass production capabilities. Moreover, the lack of standardized practices and regulations across different regions poses a barrier for companies looking to adopt 3D printing on a larger scale. As organizations navigate these obstacles, collaboration between stakeholders and further investment in research and development will be essential to unlock the full potential of 3D printing in global manufacturing.

Sustainability and 3D Printing: A New Era for Eco-Friendly Manufacturing

The advent of 3D printing technology is heralding a new era in sustainable manufacturing practices across the globe. As industries increasingly prioritize eco-friendly solutions, the integration of additive manufacturing is becoming pivotal in reducing waste and optimizing resource use. For instance, innovative applications of 3D printing are emerging in sectors like construction and fashion, where materials that were once viewed as waste—such as sugarcane remnants or wood scraps—are being revitalized into usable products. This transformative approach not only diminishes the environmental footprint but also redefines how we perceive material consumption.

Moreover, advancements in sustainable materials are reshaping industries, showcasing the potential of 3D printing to produce high-performance goods without compromising eco-consciousness. For example, new fabric innovations are on the rise, utilizing bio-based materials and other sustainable sources to create garments that minimize environmental impact. This momentum is supported by a growing commitment to practices aligned with environmental, social, and governance (ESG) principles, making sustainability a core driver for future growth in manufacturing. The shift towards responsible production methods promises to pave the way for a more sustainable industrial landscape, revolutionizing not just how products are made, but the very materials we choose to create them.

Future Innovations: What’s Next for 3D Printing Machines?

The future of 3D printing machines in global manufacturing is poised for significant advancements driven by innovation and strategic collaborations. As indicated in a recent report, the global 3D printing market is expected to reach approximately $34.8 billion by 2024, reflecting a compound annual growth rate (CAGR) of around 23% from 2020 to 2024. This growth is fueled by breakthroughs in various industries, including aerospace and healthcare, where innovative uses of 3D printing technology, such as fiber-reinforced composites, are paving the way for precision manufacturing.

Notably, the UK Atomic Energy Authority's recent acquisition of advanced 3D printing machines signifies a growing focus on creating parts that can withstand extreme conditions, particularly in the field of nuclear fusion. Similarly, emerging technologies in multi-material jetting are expanding the capabilities of 3D printers, enabling the creation of complex structures with various materials. Additionally, the integration of AI and IoT with 3D printing will likely enhance manufacturing processes by improving efficiency and sustainability, particularly in the construction of eco-friendly intelligent homes. With these trends, the landscape of global manufacturing is on the brink of transformation, driven by the relentless march of 3D printing innovations.

Future Innovations in 3D Printing Machines

This chart illustrates the projected growth in various applications of 3D printing technology in global manufacturing over the next five years. The growth percentages represent expected adoption rates across different sectors.

Related Posts

-

Mastering the Basics of Powder 3D Printing with Our Step by Step Guide

-

Understanding the Impact of Sintering 3D Printers on Modern Manufacturing Efficiency

-

Innovative Solutions for Enhancing Production with Powder 3D Printers

-

Top Strategies for Maximizing Efficiency with Sintering 3D Printers

-

Challenges Faced by Businesses in Adopting Commercial 3D Printers

-

Comprehensive Guide to Choosing the Best SLA Printers for Your Business Needs