The Future of Creative Production with 3D Plastic Printers

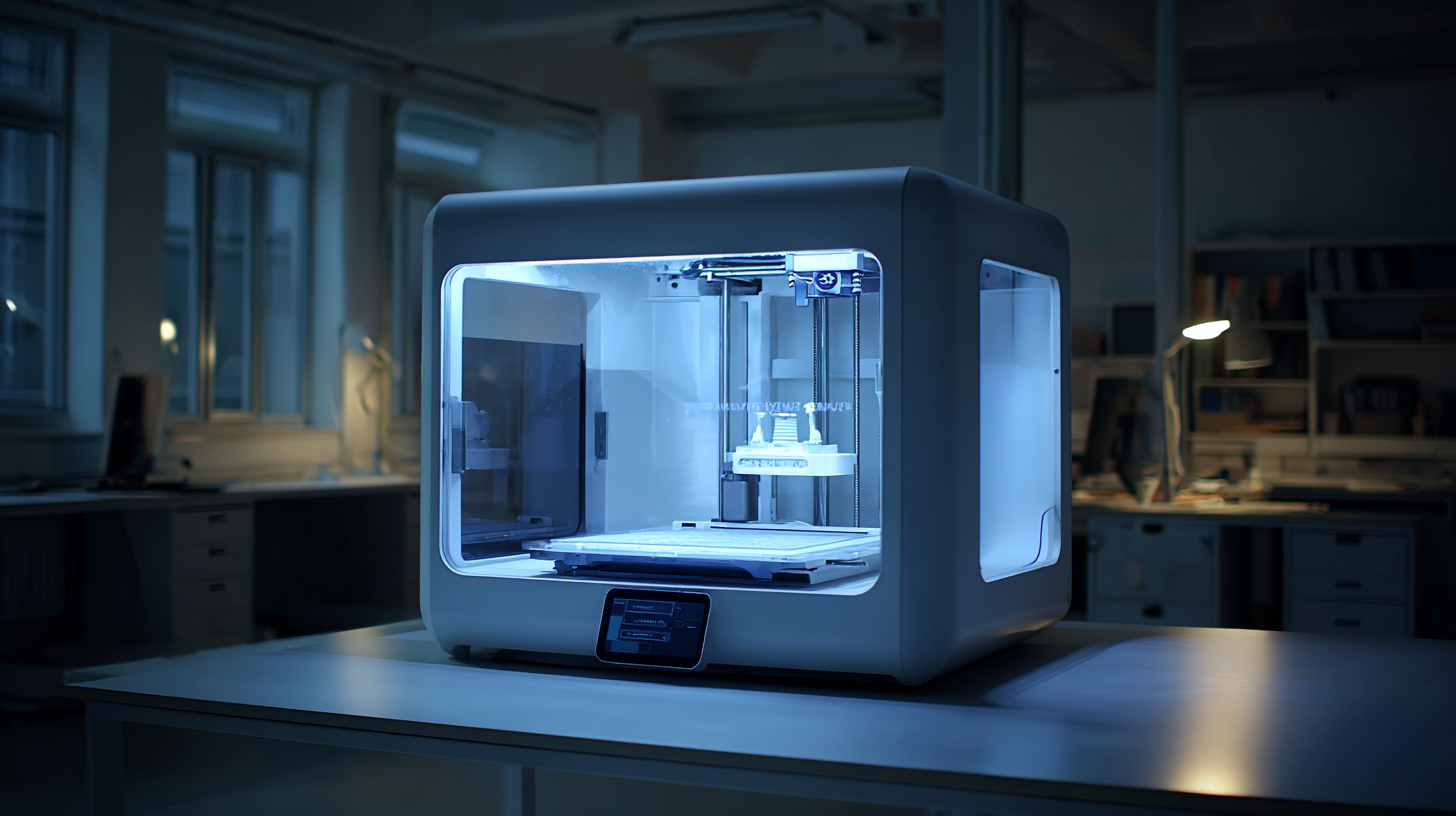

As the landscape of creative production continues to evolve, the emergence of the 3D plastic printer stands at the forefront of innovation, revolutionizing how designers and manufacturers approach their work.

According to a report by Grand View Research, the global 3D printing market is projected to reach USD 62.79 billion by 2026, highlighting a compound annual growth rate (CAGR) of 22.5% from 2019 to 2026. This exponential growth is largely driven by advancements in 3D plastic printing technologies, which enable rapid prototyping, customization, and reduced material waste.

Industries from healthcare to automotive are increasingly adopting 3D plastic printers, leveraging their capabilities to produce complex geometries and functional parts with unprecedented efficiency.

As we look to the future, it becomes clear that 3D plastic printers will not only enhance creative production but also redefine the possibilities of innovation across various sectors.

Table of Contents

[Hide]

Future Innovations in 3D Plastic Printing Technology

The advancements in 3D plastic printing technology are set to revolutionize the creative production landscape. According to a report by MarketsandMarkets, the global 3D printing market is expected to grow from $13.7 billion in 2020 to $62.5 billion by 2028, representing a compound annual growth rate (CAGR) of 18%. This surge in demand is largely driven by innovations like improved material formulations and faster printing speeds, which enhance efficiency and output quality.

Moreover, future innovations are focusing on sustainable practices, aiming to reduce waste in the production process. A study published in the Journal of Cleaner Production highlights that additive manufacturing processes can use up to 70% less material than traditional subtractive methods. As bioplastics gain traction, the integration of recycled materials into 3D printing will further promote eco-friendly production methods, aligning with global sustainability goals.

With these advancements, industries such as aerospace, automotive, and healthcare are poised to leverage 3D printing not just for prototyping, but for end-use components, pushing the boundaries of what's possible in creative production.

Applications of 3D Printing in Creative Industries

The advent of 3D printing technology has revolutionized the creative industries, enabling artists and designers to push the boundaries of their imagination. In recent years, 3D plastic printers have emerged as indispensable tools in sectors such as fashion, architecture, and product design. By allowing for the rapid prototyping of unique designs, these printers facilitate a seamless integration of art and commerce, resulting in innovative creations that captivate consumers.

Moreover, the cross-industry collaboration between creative production and commercial enterprises has sparked a new wave of artistic expression. From eye-catching installations in retail spaces to intricate designs showcased in exhibitions, the versatility of 3D printing empowers creators to materialize their concepts in ways previously thought impossible. This technological synergy not only enhances the aesthetic appeal of products but also provides brands with a competitive edge in a fast-evolving market, ultimately transforming consumer experiences and engagement.

The Future of Creative Production with 3D Plastic Printers

Sustainability and Materials: The Green Revolution in 3D Printing

The future of 3D printing is inextricably linked to sustainability, as innovations in materials are leading the charge toward a greener revolution in creative production. Recent advancements in sustainable building materials, particularly in regions like North-East India, demonstrate how 3D printing can enhance not only the affordability but also the durability of structures. By utilizing eco-friendly materials tailored for Assam-type houses, builders are able to create sustainable homes that minimize environmental impact, showcasing how 3D printing technology can effectively promote a circular economy.

Additionally, breakthroughs in green cement and concrete are transforming the construction landscape, offering alternative materials that surpass traditional options in strength while embodying carbon-negative properties. This shift toward sustainable materials is crucial for the construction industry, allowing it to prioritize eco-friendly practices. As the 3D printing revolution unfolds, it paves the way for expedited, cost-effective, and environmentally responsible solutions, especially in developing regions. The convergence of 3D printing and sustainable material innovations marks a significant step towards a more sustainable future in creative production.

Enhancing Design Flexibility and Customization Through 3D Printing

The emergence of 3D printing technology is reshaping the landscape of creative production, particularly in enhancing design flexibility and customization. As highlighted by recent industry insights, the global demand for 3D printed products is witnessing a substantial surge. Reports estimate that the on-demand printing market will reach approximately $8.03 billion by 2023, growing at a compounded annual growth rate (CAGR) of 25.18% from 2024 to 2031. This growth illustrates the increasing viability of 3D printing as a method for producing highly customized products that meet specific consumer needs.

Moreover, the integration of 3D printing in various sectors, including fashion and manufacturing, showcases its potential to revolutionize traditional production methods. For instance, advancements in additive manufacturing are enabling brands to create unique products, such as fully 3D printed footwear, which not only enhances design complexity but also reflects a shift towards more personalized consumer experiences. In the packaging sector, the market is projected to reach a staggering value of $57.93 billion by 2032, driven by innovations in printing technology and the demand for bespoke packaging solutions. The ongoing evolution of 3D printing continues to provide designers and manufacturers with unmatched flexibility, allowing them to push the boundaries of creativity and functionality.

The Future of Creative Production with 3D Plastic Printers - Enhancing Design Flexibility and Customization Through 3D Printing

| Dimension | Description | Impact on Production | Customization Level |

|---|---|---|---|

| Material Variety | Ability to use multiple types of plastic materials for different applications. | Increases product diversity and user choices. | High |

| Design Complexity | Capability to create intricate designs that are difficult to achieve with traditional methods. | Enhances aesthetic appeal and product functionality. | Very High |

| Production Speed | Reduction in time taken from design to product completion compared to traditional methods. | Leads to quicker market entry for products. | Medium |

| Cost Efficiency | Lower costs for small batch productions and prototypes. | Allows for more businesses to innovate without hefty investments. | Medium to High |

| Sustainability | Possibility of using recyclable materials and reducing waste during production. | Promotes eco-friendly manufacturing practices. | High |

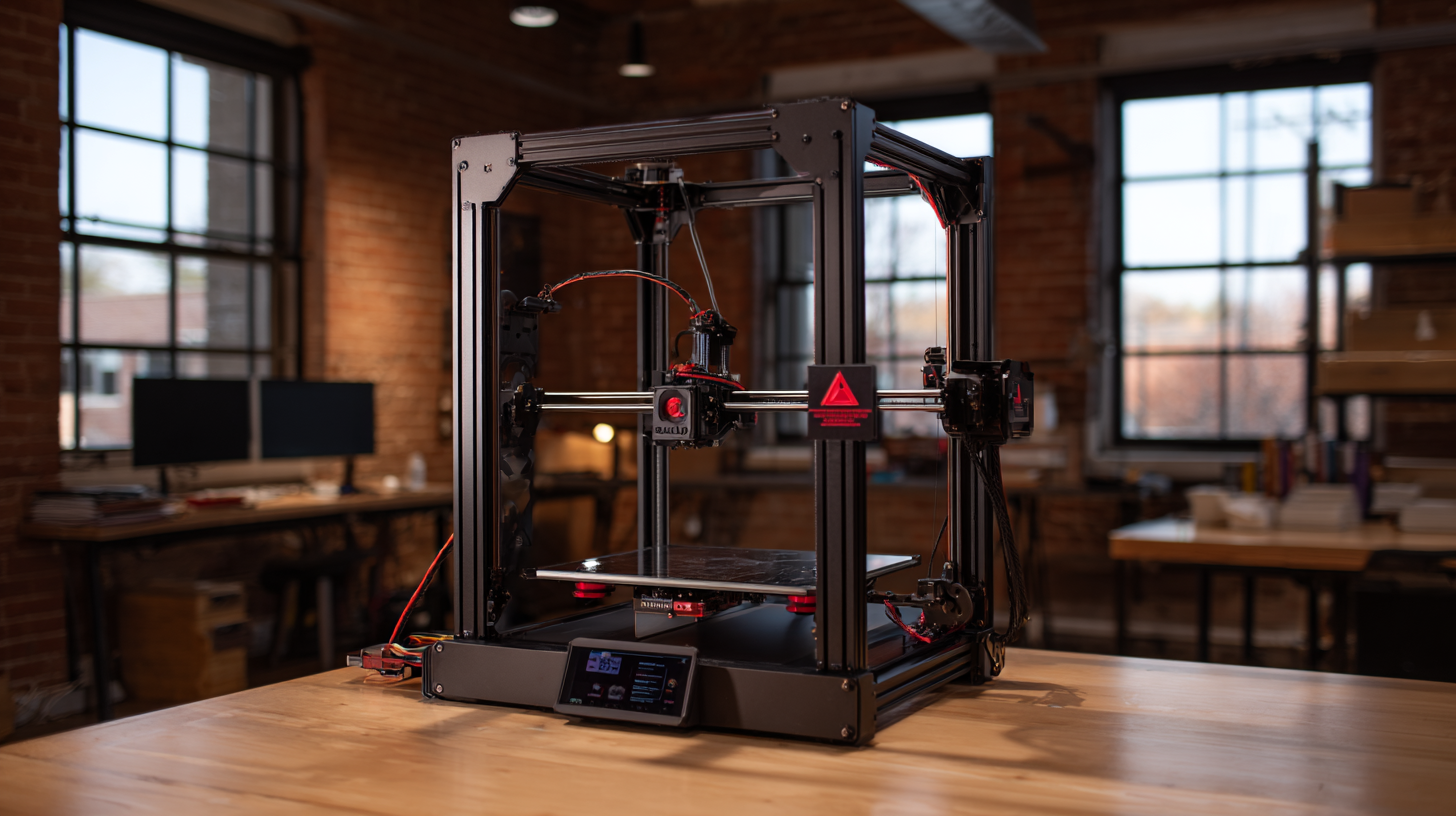

Navigating Challenges and Opportunities in 3D Creative Production

The rise of 3D plastic printers has transformed the landscape of creative production, presenting both challenges and opportunities that industry professionals must navigate. According to a report by Wohlers Associates, the global 3D printing market is expected to grow from $15.5 billion in 2020 to over $34.8 billion by 2026, underscoring the immense potential of the technology in various sectors, including arts, fashion, and product design. However, while the accessibility of 3D printing has democratized production, it also imposes a steep learning curve for designers unfamiliar with digital fabrication processes.

One of the primary challenges in 3D creative production is the material selection, which significantly impacts the final product's aesthetic and functional properties. A recent study published by SmarTech Analysis highlights that the materials market for 3D printing could reach $6.5 billion by 2027, indicating that advancements in material science will play a crucial role in enhancing creative possibilities. Consequently, designers must stay informed about emerging materials and printing technologies to leverage their full benefits. As creative professionals navigate this evolving landscape, integrating innovative tools while embracing the learning opportunities presented by 3D printing will ultimately shape the future of creative production.