Comprehensive Guide to Choosing the Best SLA Printers for Your Business Needs

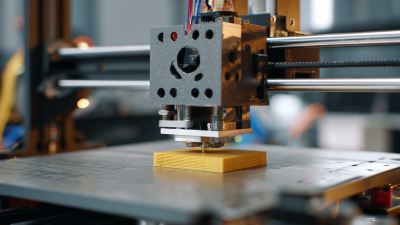

In recent years, SLA printers have garnered significant attention in the additive manufacturing landscape, especially among businesses seeking to enhance their prototyping capabilities. According to a report by MarketsandMarkets, the 3D printing market is expected to grow from $12.6 billion in 2022 to $34.8 billion by 2027, driven largely by innovations in resin-based technologies like stereolithography (SLA). As organizations look to streamline production processes, SLA printers are increasingly lauded for their ability to produce high-resolution parts with superior surface finishes and intricate details. This comprehensive guide aims to equip you with the essential knowledge needed to select the best SLA printer tailored to your business needs, factoring in efficiency, cost-effectiveness, and application suitability in an evolving manufacturing environment.

Table of Contents

[Hide]

Common Issues Faced with SLA Printers in Business Environments

When adopting SLA printers in business environments, several common issues can arise.

Many companies cite challenges related to the quality and consistency of prints, particularly when dealing with complex geometries or fine details. Variations in resin quality and printer calibration can lead to discrepancies, affecting the final product's integrity and reducing overall efficiency in production.

Additionally, the environmental impact of SLA printing materials raises concerns; the disposal of photopolymer resins can pose significant ecological risks, prompting businesses to explore more sustainable practices.

Moreover, health and safety issues are paramount in workplaces utilizing SLA printers. The emissions from 3D printing processes, including fumes and volatile organic compounds (VOCs), necessitate adequate ventilation and air purification measures to ensure a safe working environment. The integration of advanced technologies, such as AI and IoT, can facilitate better monitoring of these emissions, enhancing workplace safety while promoting eco-friendly practices.

Companies are increasingly seeking solutions that not only address the technical challenges of SLA printers but also support sustainable manufacturing and compliance with regulatory standards.

Understanding the Impact of Print Quality on Business Performance

When it comes to selecting an SLA printer for your business, understanding the impact of print quality is crucial. High-quality prints not only enhance the aesthetic appeal of your products but also significantly influence customer perception and satisfaction. In an increasingly competitive market, exceptional print quality can set your offerings apart, attracting more clients and fostering brand loyalty. Coupled with precision and detail, superior print quality can translate into functional parts that perform better, increasing efficiency and reducing rejection rates in production workflows.

Furthermore, the relationship between print quality and overall business performance extends beyond mere aesthetics. Poor-quality prints can lead to costly reworks and wasted materials, ultimately affecting your bottom line. Investing in an SLA printer that delivers consistent, high-resolution outcomes pays dividends in reducing operational costs. It is essential to assess not only the technical specifications of a printer but also the materials and curing technologies used in the printing process. By choosing a printer capable of maintaining high standards, businesses can ensure that their printed products reliably meet industry expectations and deliver value to their customers.

Challenges in Material Compatibility for SLA Printing

In the realm of SLA (Stereolithography) printing, material compatibility presents a significant challenge, particularly as the industry evolves toward multi-material applications. As recent advancements show, integrating mechanical, electrical, and thermal functionalities into a single component is key for modern manufacturing. In the automotive and aerospace sectors, the 3D printing materials market is projected to reach USD 12.4 billion by 2033, indicating a robust demand for innovative materials that can perform under challenging conditions.

The complexity of multi-material vat photopolymerization presents hurdles in achieving seamless transitions between disparate materials. This method, once seen as narrowly focused on single-material processes, is now opening pathways for the exploration of varied composites, enhancing functionality while grappling with compatibility issues. To address these challenges, businesses should carefully assess their material choices, ensuring they align with the operational requirements and desired outcomes of their projects.

**Tips:** 1) Always verify the compatibility of materials with your SLA printer to avoid print failures. 2) Consider conducting small-scale tests with new materials before full-scale production. 3) Stay informed about material innovations that offer improved performance characteristics for your specific industry needs.

Mechanical Failures: Identifying and Mitigating Risks

When selecting SLA printers for your business, it's crucial to consider mechanical failures that can impact production efficiency and product quality. Identifying potential risks involves a thorough understanding of the printer's mechanical components, such as the build platform, laser system, and resin vat. Regular maintenance checks can help spot wear and tear early, preventing unexpected downtime and costly repairs. Furthermore, keeping an eye on environmental factors, such as temperature and humidity, ensures that the printer operates under optimal conditions.

Mitigating risks associated with mechanical failures can be achieved through proactive strategies. Investing in high-quality, reliable components, and opting for models with robust warranties can significantly reduce the likelihood of issues arising. Additionally, implementing a routine maintenance schedule that includes cleaning, lubrication, and part inspections can enhance the longevity of your SLA printer. Training personnel to recognize early signs of mechanical issues can further fortify your operations against potential disruptions, allowing for a smoother workflow and better adherence to production timelines.

Comprehensive Guide to Choosing the Best SLA Printers for Your Business Needs - Mechanical Failures: Identifying and Mitigating Risks

| Printer Model | Build Volume (mm³) | Layer Resolution (μm) | Typical Cost ($) | Common Mechanical Failures | Mitigation Strategies |

|---|---|---|---|---|---|

| Model A | 300 x 300 x 400 | 50 | 5,000 | Failed Z-axis Movement | Regular Lubrication and Calibration |

| Model B | 250 x 250 x 300 | 25 | 3,500 | Resin Clog in Vat | Frequent Cleaning and Inspection |

| Model C | 200 x 200 x 250 | 10 | 2,000 | Misalignment of Build Platform | Regular Level Checks and Adjustments |

| Model D | 350 x 350 x 450 | 20 | 7,000 | Power Supply Issues | Use Surge Protectors and Uninterruptible Power Supplies |

Troubleshooting Workflow Disruptions in SLA Printing Operations

In the world of SLA (Stereolithography) printing, workflow disruptions can be a significant bottleneck impacting productivity and profitability. According to a report by Wohlers Associates, 47% of companies using additive manufacturing technologies reported ongoing operational challenges that affect their production capabilities. Common issues include equipment malfunctions, software incompatibilities, and insufficient post-processing strategies. These disruptions not only delay project timelines but also escalate operational costs, presenting a critical area for businesses to address.

To mitigate these interruptions, it is essential to adopt a proactive approach. Regular maintenance of SLA printers can help identify potential issues before they lead to downtime. Additionally, investing in high-quality materials can reduce printer strain and enhance the overall reliability of printing operations. A study from SmarTech Analysis emphasized that companies combining robust machine maintenance protocols with effective software solutions reduced downtime by up to 30%. In an environment where speedy and precise production is key, avoiding workflow disruptions is imperative for businesses looking to optimize their SLA printing operations.