Understanding the Impact of Sintering 3D Printers on Modern Manufacturing Efficiency

In recent years, the advent of sintering 3D printers has revolutionized modern manufacturing processes, significantly enhancing efficiency and reducing production costs. According to a report by Wohlers Associates, the additive manufacturing industry is projected to reach $35.6 billion by 2024, driven largely by advancements in technologies like sintering. These printers utilize selective laser sintering (SLS) techniques to fuse powdered materials, enabling the production of complex geometries that were previously unattainable with traditional manufacturing methods. This capability not only accelerates prototyping and product development timelines but also optimizes material usage, resulting in up to 70% less waste compared to conventional practices. As manufacturers seek to leverage these efficiencies, understanding the impact of sintering 3D printers becomes crucial for maintaining a competitive edge in the rapidly evolving landscape of industrial production.

Table of Contents

[Hide]

The Science Behind Sintering: How It Works in 3D Printing Technology

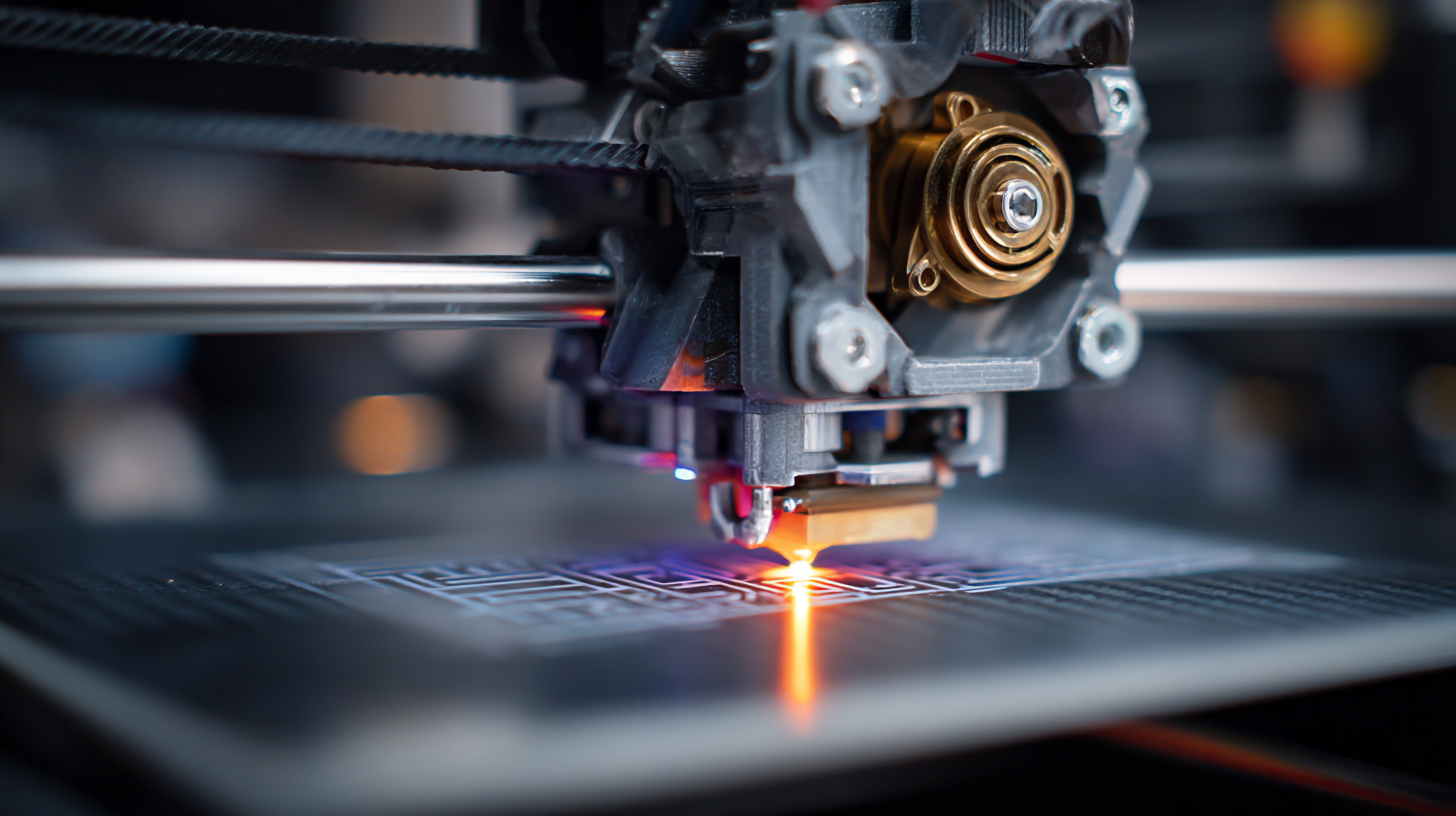

Sintering, a key process in 3D printing technology, plays a vital role in determining the mechanical properties and overall performance of printed parts. By applying heat to a compacted powder, sintering facilitates the bonding of particles, leading to enhanced density and strength in the final product. This technique is particularly important in manufacturing applications where durability and precision are paramount, such as in aerospace and automotive industries. The ability to control sintering parameters not only improves material properties but also allows for the production of complex geometries that were previously unattainable through traditional methods.

Recent studies have highlighted advancements in sintering kinetics, revealing how additives like TiO2 can optimize the process and improve the thermal shock resistance of ceramics. This scientific understanding enables manufacturers to tailor materials specifically to their application needs, pushing the boundaries of what can be achieved with 3D printing. As the industry continues to evolve, the integration of advanced sintering techniques into 3D printing workflows promises to significantly enhance manufacturing efficiency, making it a critical area of focus for future developments in additive manufacturing.

Types of Materials Used in Sintering Processes for 3D Printing

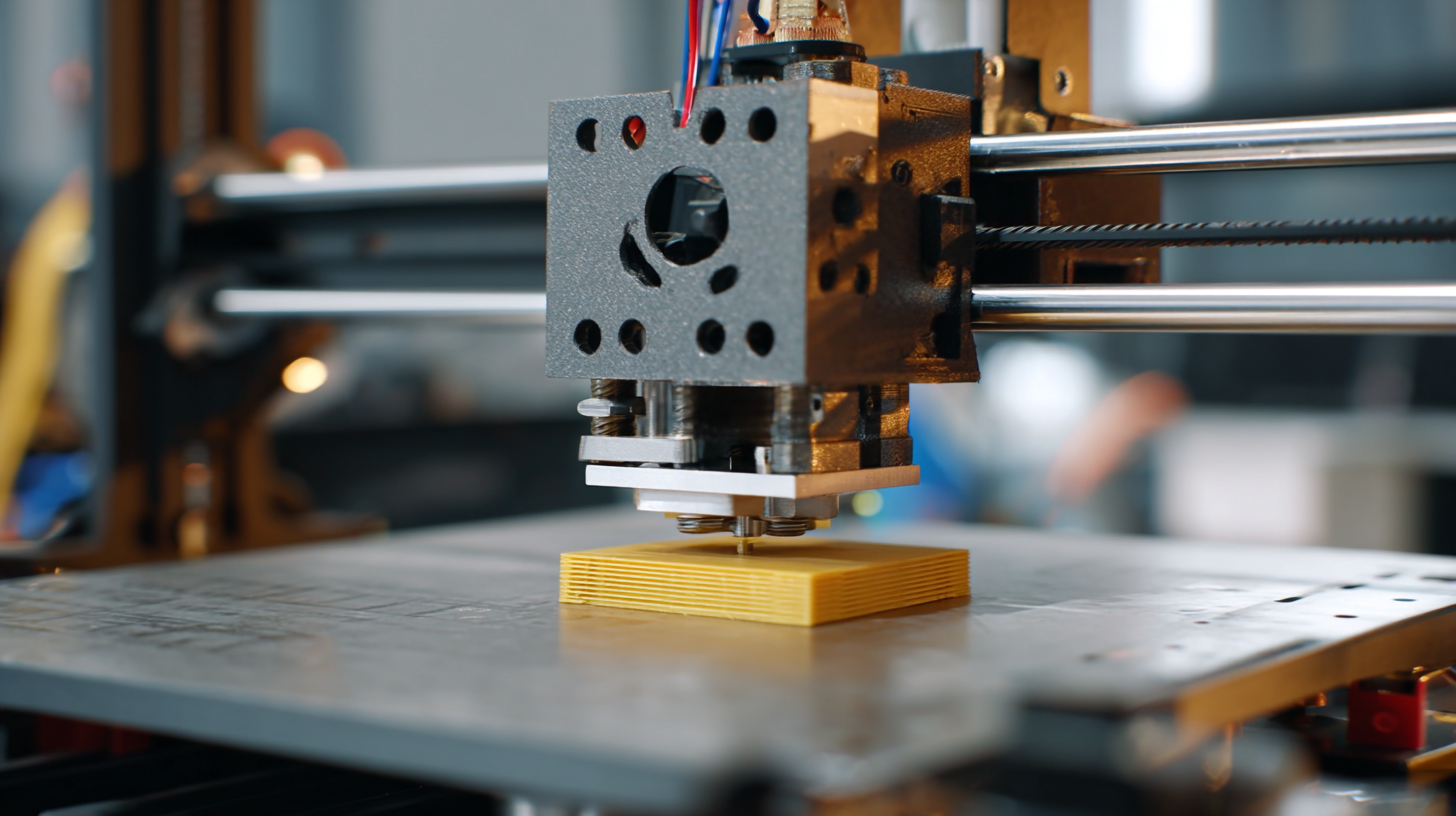

Sintering is a pivotal process in the realm of 3D printing, significantly influencing the types of materials suitable for modern manufacturing. Among the most commonly used materials in sintering processes are polymers, metals, and ceramics, each imparting unique properties to the final product. Polymer-based materials, such as nylon and polyamide, are widely appreciated for their lightweight and durable characteristics, making them ideal for functional prototypes and end-use parts alike. Their versatility allows for intricate designs that traditional manufacturing methods often struggle to achieve.

Metals, particularly powdered forms like stainless steel and titanium, have become essential in sintering for applications requiring superior strength and heat resistance. The ability to produce complex geometries using metal powders not only enhances design freedom but also optimizes material usage, reducing waste. Similarly, ceramics offer exceptional hardness and thermal stability, ideal for high-performance applications in industries like aerospace and automotive. The ongoing research into advanced materials continues to expand the horizons of sintering technology, promising to drive innovative manufacturing solutions in the near future.

Impact of Sintering 3D Printers on Manufacturing Efficiency

Efficiency Gains: Comparing Sintering with Traditional Manufacturing Methods

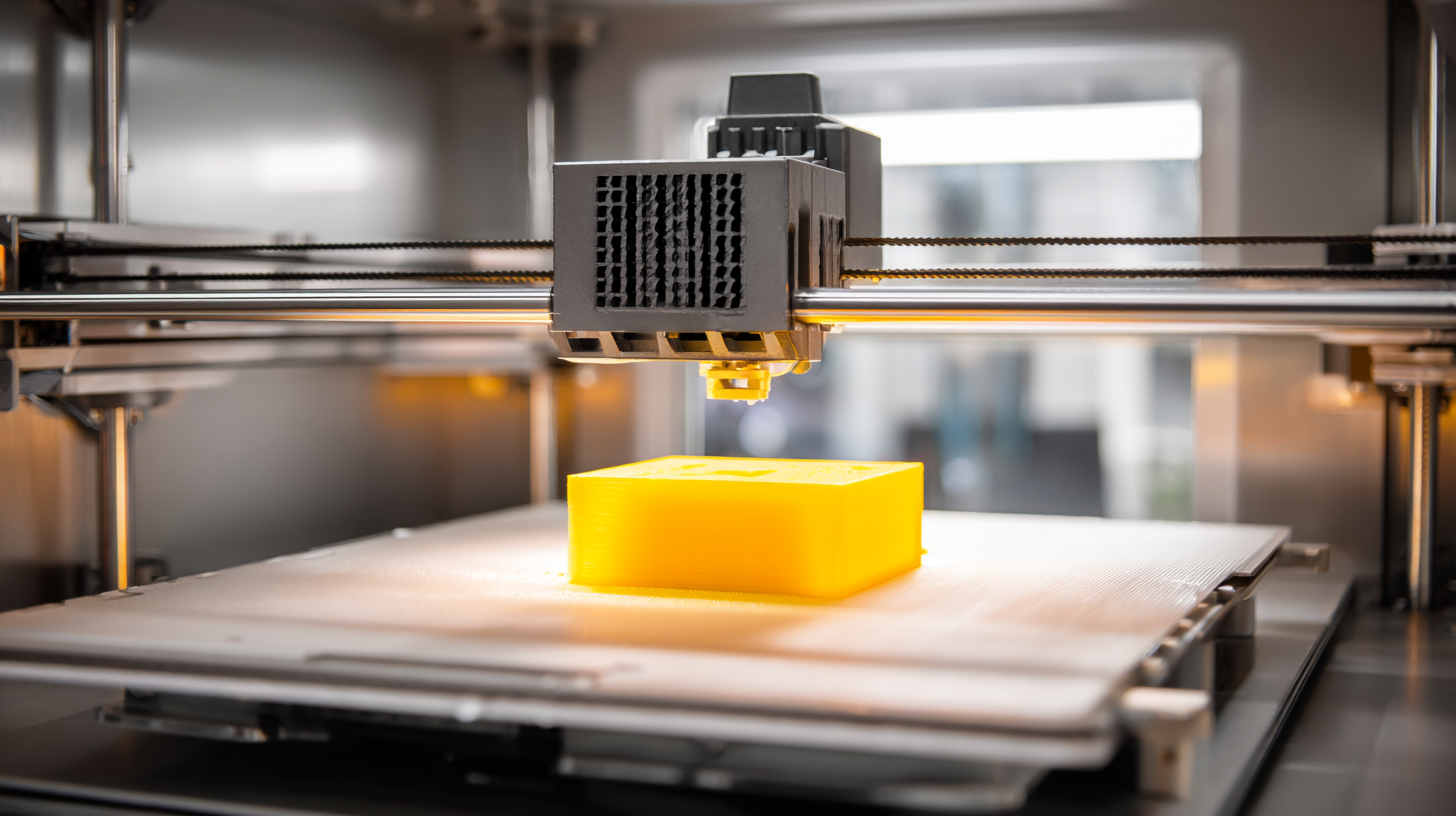

Sintering 3D printers have emerged as a game-changing technology in the landscape of modern manufacturing, especially when compared to traditional methods. According to a report by Wohlers Associates, the additive manufacturing industry is projected to grow to over $40 billion by 2025, with sintering technology playing a crucial role in this transformation. One of the most significant efficiency gains associated with sintering is the drastic reduction in material waste. Traditional machining processes often generate waste rates of 30-50%, while sintering can achieve waste rates as low as 5%, thus optimizing material utilization and reducing costs.

Moreover, sintering 3D printing accelerates production times significantly. Recent studies indicate that prototyping and manufacturing lead times can be reduced by up to 70% when using sintering technologies compared to conventional methods. This speed not only benefits large-scale production but also allows for quicker iterations and more innovative designs. Enhanced design complexity achievable through sintering further supports this efficiency, enabling manufacturers to produce intricate parts that would be difficult or impossible to create through subtractive manufacturing techniques. As a result, industries are increasingly adopting sintering for its ability to improve throughput while maintaining high-quality standards.

Understanding the Impact of Sintering 3D Printers on Modern Manufacturing Efficiency

| Manufacturing Method | Production Time (Hours) | Material Wastage (%) | Setup Cost ($) | Production Volume (Units) |

|---|---|---|---|---|

| Sintering 3D Printing | 24 | 5 | 1500 | 100 |

| Traditional Machining | 40 | 20 | 2200 | 80 |

| Injection Molding | 30 | 10 | 3000 | 200 |

| Casting | 50 | 15 | 2500 | 150 |

Real-World Applications: Industries Transforming Through Sintering 3D Printers

Sintering 3D printers are revolutionizing various industries by significantly enhancing manufacturing efficiency and product quality. In sectors like aerospace and automotive, sintered components exhibit remarkable strength-to-weight ratios, with some reports indicating a reduction in material waste by up to 50%. This process allows manufacturers to produce intricate designs that were previously impossible with traditional methods. For instance, the aerospace industry has begun implementing sintered parts that can endure extreme conditions, thereby reducing the overall mass of aircraft, which translates to lower fuel consumption and operational costs.

Sintering 3D printers are revolutionizing various industries by significantly enhancing manufacturing efficiency and product quality. In sectors like aerospace and automotive, sintered components exhibit remarkable strength-to-weight ratios, with some reports indicating a reduction in material waste by up to 50%. This process allows manufacturers to produce intricate designs that were previously impossible with traditional methods. For instance, the aerospace industry has begun implementing sintered parts that can endure extreme conditions, thereby reducing the overall mass of aircraft, which translates to lower fuel consumption and operational costs.

One of the key areas where sintering technology shines is in the production of medical devices, where precision and customization are paramount. According to a recent study, the additive manufacturing of dental prosthetics using sintering methods can cut production time by 60% compared to conventional techniques. This rapid turnaround allows dental professionals to meet patient needs more efficiently and with higher accuracy.

Tip: When implementing sintering technology, ensure to conduct thorough material analysis to choose the best powder for your specific application, as the material properties play a vital role in determining the final product's performance.

Tip: Collaborate with suppliers and industry experts to leverage best practices in the sintering process, which can lead to improved quality and reduced production cycles, ultimately enhancing overall operational efficiency.

Future Trends: Innovations in Sintering Techniques for Enhanced Productivity

The evolution of sintering techniques is poised to redefine productivity within modern manufacturing. As industries increasingly adopt 3D printing, innovations in sintering processes are emerging to maximize efficiency and minimize production times. Advanced methods, such as binder jetting combined with rapid microwave sintering, are paving the way for much faster fabrication of complex parts. These innovative approaches not only reduce energy consumption but also enhance the mechanical properties of the final products, making them more viable for critical applications in aerospace and automotive sectors.

Moreover, the integration of smart technology into sintering processes is set to revolutionize manufacturing workflows. By leveraging real-time data analytics and machine learning algorithms, manufacturers can optimize parameters such as temperature and pressure during sintering, leading to improvements in yield and consistency. The ability to monitor and adjust sintering parameters on-the-fly means that production lines can operate with greater flexibility and responsiveness to demand changes. This adaptive approach not only accelerates production cycles but also supports the customization of parts to meet specific client needs, ultimately driving innovation across industries.