Innovative Solutions for Enhancing Production with Powder 3D Printers

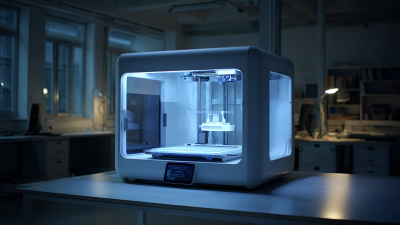

The rise of powder 3D printers is transforming the manufacturing landscape by offering innovative solutions that significantly enhance production capabilities. As per a recent market report by Smithers, the global 3D printing market is expected to reach $34.8 billion by 2026, with powder-based printing technologies accounting for a considerable share due to their ability to produce highly complex geometries with remarkable precision. This advancement is particularly pivotal in industries such as aerospace and healthcare, where lightweight, custom components are in high demand. Moreover, a study from Wohlers Associates highlights that over 70% of manufacturers are adopting additive manufacturing techniques, with powder 3D printing emerging as a frontrunner due to its efficiency and versatility. Thus, exploring the benefits of powder 3D printers provides a window into the future of production, where innovation and technology converge to drive unprecedented growth and efficiency.

The rise of powder 3D printers is transforming the manufacturing landscape by offering innovative solutions that significantly enhance production capabilities. As per a recent market report by Smithers, the global 3D printing market is expected to reach $34.8 billion by 2026, with powder-based printing technologies accounting for a considerable share due to their ability to produce highly complex geometries with remarkable precision. This advancement is particularly pivotal in industries such as aerospace and healthcare, where lightweight, custom components are in high demand. Moreover, a study from Wohlers Associates highlights that over 70% of manufacturers are adopting additive manufacturing techniques, with powder 3D printing emerging as a frontrunner due to its efficiency and versatility. Thus, exploring the benefits of powder 3D printers provides a window into the future of production, where innovation and technology converge to drive unprecedented growth and efficiency.

Table of Contents

[Hide]

Understanding Powder 3D Printing: Key Technologies and Processes

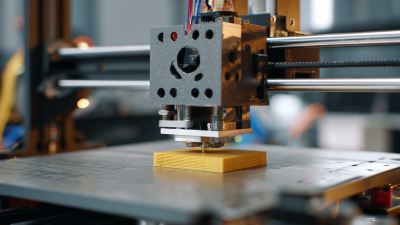

Powder 3D printing has emerged as a groundbreaking technology in additive manufacturing, significantly impacting industries ranging from aerospace to medical devices. Understanding the key technologies and processes behind powder 3D printing is essential for companies aiming to enhance production efficiency. Techniques such as

Selective Laser Sintering (SLS) and

Multi Jet Fusion (MJF) allow for the creation of complex geometries with excellent material properties. According to a report by Grand View Research, the global 3D printing market is expected to reach $62.79 billion by 2028, with powder-based printing solutions playing a crucial role in this growth due to their ability to produce lightweight yet durable parts.

Powder 3D printing has emerged as a groundbreaking technology in additive manufacturing, significantly impacting industries ranging from aerospace to medical devices. Understanding the key technologies and processes behind powder 3D printing is essential for companies aiming to enhance production efficiency. Techniques such as

Selective Laser Sintering (SLS) and

Multi Jet Fusion (MJF) allow for the creation of complex geometries with excellent material properties. According to a report by Grand View Research, the global 3D printing market is expected to reach $62.79 billion by 2028, with powder-based printing solutions playing a crucial role in this growth due to their ability to produce lightweight yet durable parts.

Tip: Choose the right powder material for your application. Different powders, such as Nylon, metal alloys, and ceramics, offer unique benefits. For instance, Nylon is well-suited for functional prototypes and end-use parts, while metal powders like titanium are preferred in the aerospace industry for their strength-to-weight ratio.

Moreover, optimizing the printing process is equally vital. Parameters such as laser speed, layer thickness, and temperature can dramatically affect the quality of the final product. A study from the University of California shows that precise control over these parameters can lead to a 30% increase in mechanical properties of parts produced by SLS.

Tip: Implement proper post-processing techniques. Post-processing, including heat treatment and surface finishing, can further enhance the mechanical and aesthetic qualities of the printed parts, making them ready for high-performance applications. Investing in these techniques ensures that the parts not only meet industry standards but also perform maximally under operational stresses.

Advantages of Powder 3D Printers in Modern Manufacturing Practices

Powder 3D printing, particularly through methods such as Wire Arc Additive Manufacturing (WAAM), has emerged as a pivotal innovation in modern manufacturing. The inherent advantages of this technology include a rapid deposition rate and cost-effectiveness, making it an attractive option for companies looking to maximize efficiency. The ability to produce complex geometries and structures with a variety of metal powders opens up new possibilities for industries ranging from automotive to aerospace. This flexibility allows manufacturers to iterate designs quickly and tailor components to specific needs, thus enhancing overall production capabilities.

Moreover, the application of powder 3D printing in spare parts production is transforming supply chain dynamics. By leveraging this technology, companies can create components on demand, significantly reducing lead times and the necessity for large physical inventories. This shift not only optimizes warehouse space but also minimizes waste, contributing to more sustainable manufacturing practices. As industries continue to embrace these advanced methodologies, the implications for operational efficiency and design innovation are profound, positioning powder 3D printing as a cornerstone of future manufacturing strategies.

Innovative Applications of Powder 3D Printing Across Various Industries

Powder 3D printing has emerged as a transformative technology across various industries, pushing the boundaries of traditional manufacturing. In the aerospace sector, for instance, aerospace companies are utilizing powder 3D printing to create lightweight components that not only enhance fuel efficiency but also reduce production time. By enabling complex geometries that are impossible to achieve with conventional methods, powder 3D printing allows for innovations like internal lattice structures, which provide strength without unnecessary weight.

Similarly, the automotive industry is embracing this technology for rapid prototyping and custom part production. Automotive manufacturers can produce bespoke components on-demand, minimizing inventory costs and maximizing design flexibility. Additionally, the medical field is witnessing revolutionary advancements with personalized medical implants and prosthetics crafted through powder 3D printing. This technology enables tailored solutions that fit the unique anatomies of individual patients, contributing to better surgical outcomes and improved patient care. As industries continue to explore the potential of powder 3D printing, the possibilities for innovation appear boundless.

Challenges and Solutions in Powder 3D Printing Implementation

The implementation of powder 3D printing faces several challenges, particularly concerning material compatibility and processing techniques. One prominent issue is the effective use of recycled plastics and biomass waste, which can significantly enhance sustainability within the additive manufacturing sector. Integrating these materials into the 3D printing process requires innovative methods to ensure optimal material properties and performance. Researchers are actively exploring solutions to upcycle waste products, creating sustainable polymer blends that can be utilized in powder 3D printers.

Another challenge is found in the pharmaceutical applications of powder 3D printing, where precision and customization are paramount. The ability to produce patient-specific dosage forms presents opportunities but also demands rigorous validation of the printing processes and materials used. Techniques such as semi-solid extrusion have emerged as potential solutions, providing personalized drug delivery systems that can improve patient outcomes. Continued research and collaboration among industry experts are essential for overcoming these hurdles and unlocking the full potential of powder 3D printing across various sectors.

| Challenge | Solution | Impact | Material Type | Application Area |

|---|---|---|---|---|

| Powder Flow Issues | Implementing advanced powder handling systems | Increased production efficiency | Metals, Polymers | Aerospace, Automotive |

| Material Consistency | Regular material quality checks and controls | Higher part quality and reliability | Ceramics, Metals | Healthcare, Industrial Design |

| Post-Processing Requirements | Developing automated post-processing solutions | Reduced labor costs and time | Alloy, Composite | Tooling, Manufacturing |

| Cost of Equipment | Investing in more affordable technology | Broader access to 3D printing | Plastic, Metal | Consumer Goods, Jewelry |

| Technical Expertise | Providing training and support for users | Enhanced user capability and output | Metals, Polymers | Education, Construction |

Future Trends in Powder 3D Printing and Production Efficiency Enhancements

The landscape of powder 3D printing is rapidly evolving, with future trends promising significant advancements in production efficiency. One of the most impactful innovations is the development of advanced materials that enhance the mechanical properties of printed objects. These materials not only provide better durability but also reduce the need for extensive post-processing, leading to shorter production cycles. As manufacturers integrate smart materials into their processes, we can expect to see an uptick in the versatility of applications, ranging from aerospace components to intricate medical devices.

Moreover, the advent of automation and AI-driven solutions is set to revolutionize powder 3D printing workflows. Automation can streamline the loading and unloading of materials, while AI algorithms can optimize printing parameters in real time to ensure consistent quality and minimize material waste. By harnessing these technologies, companies will be able to increase their production rates while maintaining high precision. As these trends continue to unfold, they will not only enhance operational efficiency but also redefine the benchmarks for quality and performance in the industry.