Mastering the Basics of Powder 3D Printing with Our Step by Step Guide

As the additive manufacturing landscape evolves, powder 3D printing has emerged as a game-changer across various industries, from aerospace to healthcare. According to a report by MarketsandMarkets, the powder 3D printing market is projected to grow from $1.22 billion in 2021 to $4.18 billion by 2026, showcasing a robust CAGR of 27.3%. This remarkable growth is fueled by advancements in technology and material science, making it crucial for both beginners and experienced practitioners to master the fundamentals of this process. Our step-by-step guide aims to demystify powder 3D printers, providing essential tips and techniques to harness their potential effectively. Whether you're looking to optimize your production processes or explore new design possibilities, understanding the basics will set you on the right path towards successful 3D printing endeavors.

Table of Contents

[Hide]

Understanding the Different Types of Powder 3D Printing Technologies

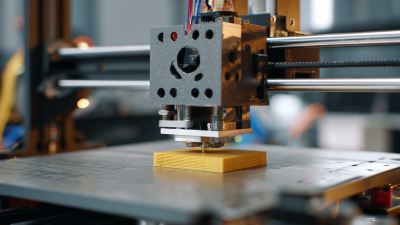

Powder 3D printing technologies have transformed the manufacturing landscape, offering unique advantages and capabilities compared to traditional methods. At the core of these technologies lies a diverse range of techniques, each with its own distinct approach to creating three-dimensional objects. Among the most notable are Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Direct Metal Laser Sintering (DMLS). Each of these processes utilizes powdered materials, whether plastics or metals, to produce intricate parts with high precision and strength.

Selective Laser Sintering employs a high-powered laser to fuse powdered material layer by layer, making it ideal for creating complex geometries without the need for support structures. On the other hand, Multi Jet Fusion enhances production efficiency by using a liquid binding agent to selectively fuse the powder, resulting in fully functional parts with superior surface finish. For metal applications, Direct Metal Laser Sintering offers unprecedented capabilities in fabricating dense, high-performance components, allowing for the production of intricate designs that are often impossible to achieve using conventional machining techniques. Understanding these different types of powder 3D printing technologies is essential for selecting the right method for your specific application and achieving optimal results.

Common Challenges Faced in Powder 3D Printing Processes

Powder 3D printing has revolutionized the manufacturing landscape, offering unparalleled design freedom and efficiency. However, like any emerging technology, it comes with its own set of challenges. One of the most common issues faced during the powder 3D printing process is the inconsistency in powder flowability. If the powder particles are too angular or not uniform in size, it can lead to poor layer deposition, resulting in weak structures and unpredictable print outcomes. Ensuring that the powder is well-suited for the specific printer and process can mitigate this challenge.

Another significant hurdle is the thermal management within the printing process. Improper temperature control can lead to issues such as warping or cracking of the printed part as it cools. Additionally, the interaction between the heat source and the powder bed plays a crucial role in determining the final properties of the printed object. Finding the right balance in thermal settings is essential for producing high-quality prints that meet the desired specifications. Addressing these challenges through diligent process refinement and advanced monitoring techniques is key to unlocking the full potential of powder 3D printing.

Tips for Optimizing Print Quality in Powder 3D Printing

In the realm of powder 3D printing, optimizing print quality is crucial for achieving accurate and reliable results. One of the key techniques to enhance the quality of prints involves adjusting the support structures effectively. As certain parts can warp or deform during the printing process, as seen with selective laser melting (SLM) technology, a well-designed support structure can significantly minimize these issues. By tailoring these supports to the unique geometry of each part, manufacturers can ensure greater stability throughout the build process.

Another aspect of improving print quality lies in the material selection and preparation. Utilizing advanced polymer composites can unlock new potential in 3D printing, particularly in fields such as aerospace and civil infrastructure. The latest advancements have demonstrated that the integration of fiber-reinforced composites not only enhances the mechanical properties of printed objects but also contributes to better surface finish and dimensional accuracy. By leveraging these materials, along with refining printing parameters and processes, users can achieve optimal results in their powder 3D printing endeavors.

Mastering the Basics of Powder 3D Printing with Our Step by Step Guide - Tips for Optimizing Print Quality in Powder 3D Printing

| Parameter | Recommended Value | Impact on Quality |

|---|---|---|

| Layer Thickness | 0.1 - 0.2 mm | Affects surface finish and detail |

| Print Speed | 50 - 100 mm/s | Balancing time vs quality |

| Powder Size | 20 - 40 microns | Influences layer adhesion and object strength |

| Bed Temperature | 80 - 120 °C | Affects warping and print stability |

| Infill Density | 10% - 100% | Alters strength and weight |

| Cooling Fan Speed | 0 - 100% | Prevents overheating and improves detail |

Post-Processing Techniques for Powder 3D Printed Parts

Post-processing is a critical phase in the powder 3D printing workflow that significantly enhances the quality and performance of printed parts. Techniques such as powder removal, heat treatment, and surface finishing can transform parts from raw to ready-for-use in applications ranging from aerospace to medical devices. According to a report by the Wohlers Associates, around 26% of additive manufacturing users identified post-processing as a critical step in achieving the desired part properties, emphasizing its importance in the overall manufacturing process.

One widely used technique in post-processing is the application of a heat treatment. This process not only helps in relieving internal stresses within the printed parts but also optimizes their mechanical properties. Research published in the "Journal of Manufacturing Science and Engineering" indicates that heat-treated components can exhibit strength increases of up to 30%. Another essential aspect of post-processing is surface finishing, which can include methods like sanding, chemical smoothing, or polishing to achieve the desired aesthetic and functional characteristics. As per a recent study by Smartech Publishing, the market for post-processing solutions in additive manufacturing is projected to grow at a CAGR of 28% through 2025, highlighting the escalating demand for high-quality finished parts in various industries.

Troubleshooting Common Problems in Powder 3D Printing

Troubleshooting common problems in powder 3D printing can significantly enhance your printing experience and output quality. One of the most frequent issues that users encounter is poor layer adhesion, which can lead to weak prints and structural failures. This problem often arises from incorrect print temperatures or material inconsistencies. To address this, it's essential to ensure that your printer settings are optimized based on the specific powder you're using. Regularly checking the temperature readings and using high-quality materials can mitigate these adhesion issues, resulting in stronger, more reliable prints.

Another common challenge in powder 3D printing is unwanted warping. Warping occurs when the temperature differential between the layers causes them to shrink unevenly as they cool. To reduce this effect, consider adjusting the platform temperature and using a heated build chamber to maintain a consistent thermal environment. Additionally, implementing effective design strategies, such as adding support structures or optimizing the orientation of your prints, can drastically decrease the likelihood of warping and improve overall print quality. By proactively addressing these concerns, you can enjoy smoother powder 3D printing experiences and achieve your desired results.

Common Troubleshooting Issues in Powder 3D Printing

Related Posts

-

Innovative Solutions for Enhancing Production with Powder 3D Printers

-

Understanding the Impact of Sintering 3D Printers on Modern Manufacturing Efficiency

-

Top Strategies for Maximizing Efficiency with Sintering 3D Printers

-

Comprehensive Guide to Choosing the Best SLA Printers for Your Business Needs

-

5 Reasons Why Desktop SLS Printers Are Revolutionizing Small Scale Manufacturing

-

The Future of Creative Production with 3D Plastic Printers