Top Strategies for Maximizing Efficiency with Sintering 3D Printers

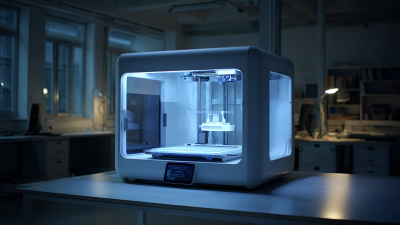

As the additive manufacturing landscape evolves, the role of sintering 3D printers in accelerating production efficiency is becoming increasingly critical. According to a report by MarketsandMarkets, the global 3D printing market is projected to reach USD 62.79 billion by 2028, with a compound annual growth rate (CAGR) of 21% from 2021 to 2028. Sintering 3D printers, which leverage advanced materials and precision engineering, are at the forefront of this growth, enabling manufacturers to produce complex geometries with enhanced mechanical properties. This transformative technology not only reduces material waste but also cuts down on production times, marking a significant shift in manufacturing strategies. As industries seek to optimize their processes and stay competitive, understanding and implementing effective strategies related to sintering 3D printers will be essential for future success.

As the additive manufacturing landscape evolves, the role of sintering 3D printers in accelerating production efficiency is becoming increasingly critical. According to a report by MarketsandMarkets, the global 3D printing market is projected to reach USD 62.79 billion by 2028, with a compound annual growth rate (CAGR) of 21% from 2021 to 2028. Sintering 3D printers, which leverage advanced materials and precision engineering, are at the forefront of this growth, enabling manufacturers to produce complex geometries with enhanced mechanical properties. This transformative technology not only reduces material waste but also cuts down on production times, marking a significant shift in manufacturing strategies. As industries seek to optimize their processes and stay competitive, understanding and implementing effective strategies related to sintering 3D printers will be essential for future success.

Table of Contents

[Hide]

Understanding Sintering: The Key Process in 3D Printing Efficiency

Sintering is a critical process in advancing the efficiency of 3D printing technologies, particularly in the production of complex metal and ceramic parts. This thermal treatment involves heating powdered materials to a temperature that is below their melting point, allowing the particles to bond together and form a solid structure. By understanding the mechanics of sintering, manufacturers can optimize their printing parameters to achieve a balance between speed and part quality, ultimately enhancing production efficiency.

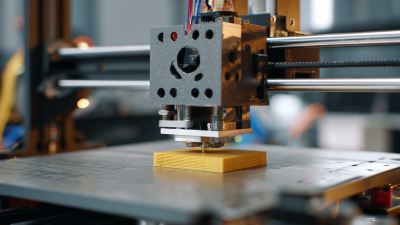

Key factors influencing sintering efficiency include temperature control, dwell time, and atmosphere within the sintering chamber. Precise temperature management ensures that the material reaches the ideal state for bonding without risking deformation or degradation. Additionally, optimizing the dwell time—how long the powder is held at high temperatures—can significantly impact the final properties of the printed parts. The use of an inert atmosphere can further prevent oxidation and other detrimental reactions, leading to higher-quality outcomes. By fine-tuning these parameters, operators can maximize throughput while minimizing defects, making sintering a quintessential aspect of effective 3D printing processes.

Essential Materials for Optimal Sintering in 3D Printing

When it comes to maximizing efficiency in sintering 3D printing, the choice of materials is paramount. Essential materials such as metal powders, ceramics, and polymers can significantly influence the outcome of the sintering process. According to a report by SmarTech Analysis, the market for metal 3D printing materials is expected to reach $3.4 billion by 2025, underscoring the growing importance of high-quality input materials in achieving desired mechanical properties and surface finishes.

Tips: Always choose high-purity materials to prevent contamination, which can result in defects and lower mechanical performance. Regularly assess your material suppliers to ensure they comply with industry standards like ISO 9001, which guarantees quality control during material production.

Furthermore, the right blend of materials can enhance the overall efficiency of your sintering process. The addition of additives can help in reducing sintering temperatures and improving the flowability of the powders, ultimately resulting in faster build times and cost savings. A recent study published in the Journal of Materials Processing Technology highlights that using optimized particle size distributions can lead to a 20% reduction in sintering energy consumption, providing a compelling reason to experiment with material formulations.

Tips: Experiment with different particle sizes to find the optimal mix for your specific applications. Keep detailed records of your sintering experiments to identify trends that can inform future material choices for improved efficiency.

Techniques to Enhance Sintering Temperature Control

Temperature control is crucial in the sintering process of 3D printing, as it directly impacts the material properties and overall print quality. One effective technique for enhancing temperature control is the implementation of advanced thermal sensors. By integrating high-precision thermocouples or infrared sensors within the printer, operators can monitor and adjust the sintering temperature in real-time. This ensures that the material reaches its optimal sintering point, resulting in improved density and strength while minimizing defects.

Temperature control is crucial in the sintering process of 3D printing, as it directly impacts the material properties and overall print quality. One effective technique for enhancing temperature control is the implementation of advanced thermal sensors. By integrating high-precision thermocouples or infrared sensors within the printer, operators can monitor and adjust the sintering temperature in real-time. This ensures that the material reaches its optimal sintering point, resulting in improved density and strength while minimizing defects.

Another strategy is to utilize controlled heating elements in the build chamber. These elements can provide uniform heat distribution, reducing thermal gradients that may lead to warping or uneven sintering. Employing a feedback loop that adjusts the heating elements based on sensor data allows for dynamic control of the temperature throughout the printing process, accommodating any fluctuations in material behavior. This level of precision not only enhances the quality of the final product but also contributes to greater efficiency in the overall production workflow.

Leveraging Software Tools for Better Sintering Predictions

In the realm of additive manufacturing, particularly with sintering 3D printers, the role of software tools has become increasingly pivotal in optimizing production processes. According to a recent report by Wohlers Associates, the global 3D printing industry is expected to grow from $12.6 billion in 2020 to over $35 billion by 2026, underscoring the necessity for efficient methodologies. By leveraging advanced software tools, manufacturers can enhance their sintering predictions, thereby reducing material waste and increasing part quality. Tools that integrate machine learning algorithms can analyze previous sintering cycles and provide data-driven forecasts, helping operators understand the optimal conditions for different materials.

Furthermore, studies conducted by the Additive Manufacturing Users Group reveal that companies utilizing software for simulation and optimization experience up to a 30% reduction in production time. This efficiency gain not only bolsters profitability but also accelerates time-to-market for innovative products. In the competitive landscape of 3D printing, where every second counts, the implementation of robust software solutions for better sintering predictions is no longer a luxury, but a necessity. As manufacturers continue to embrace these technologies, the potential for maximizing efficiency within sintering processes grows exponentially, setting a new standard for excellence in the industry.

Top Strategies for Maximizing Efficiency with Sintering 3D Printers - Leveraging Software Tools for Better Sintering Predictions

| Strategy | Software Tool | Efficiency Improvement (%) | Key Benefits |

|---|---|---|---|

| Pre-Sintering Simulation | Simulation Manager Pro | 30 | Reduces material waste and optimizes design before printing. |

| Real-Time Monitoring | Print Insight Tracker | 25 | Allows immediate adjustments to process parameters during sintering. |

| Post-Processing Optimization | Fusion Enhancer Suite | 20 | Improves surface finish and mechanical properties post-sintering. |

| Data Analytics for Prediction | DataWise Analytics | 35 | Enhances prediction accuracy for sintering outcomes based on historical data. |

Maintenance Practices to Improve Sintering Printer Longevity and Performance

Maintaining a sintering 3D printer is crucial for ensuring both its longevity and optimal performance. One of the key practices involves regular cleaning of the printer components. This includes the heating elements and build chamber, which can accumulate residues from previous prints. By using appropriate cleaning agents and methods, operators can minimize build-up that could interfere with future printing processes. Regular inspections are also vital. Checking for wear and tear on essential parts, such as the thermal sensors and support structures, can help in identifying issues before they escalate into costly repairs.

Another important maintenance practice is maintaining a consistent operating environment. Sintering printers require specific temperature and humidity conditions to function effectively. Investing in environmental monitoring equipment can aid in maintaining these parameters, thus reducing the risk of material warping and ensuring uniform sintering. Moreover, routinely calibrating the printer ensures that it operates at peak efficiency. This includes adjusting the sintering parameters and ensuring that all software aligns with the latest updates. Such proactive measures not only enhance the performance of the printer but also extend its operational life, leading to more efficient overall production.

Related Posts

-

5 Reasons Why Desktop SLS Printers Are Revolutionizing Small Scale Manufacturing

-

Comprehensive Guide to Choosing the Best SLA Printers for Your Business Needs

-

The Future of Creative Production with 3D Plastic Printers

-

Innovative Solutions for Enhancing Production with Powder 3D Printers

-

Challenges Faced by Businesses in Adopting Commercial 3D Printers

-

Understanding the Impact of Sintering 3D Printers on Modern Manufacturing Efficiency