How to Optimize Your Workflow with a Professional 3D Printer: Insights from Industry Experts

The landscape of manufacturing is undergoing a significant transformation, largely driven by advances in technology, particularly through the use of a professional 3D printer. A recent report by Smithers Pira indicates that the global market for 3D printing is expected to reach $41 billion by 2027, reflecting a compound annual growth rate of 23%. This rapid growth underscores the increasing role of 3D printing in various industries, including aerospace, automotive, and healthcare. Industry experts emphasize that optimizing workflows with a professional 3D printer not only enhances production efficiency but also allows for greater design flexibility and innovation. By integrating 3D printing into their operations, companies can significantly reduce cycle times and costs while being able to prototype and produce complex geometries that traditional manufacturing methods cannot achieve. This article aims to provide insights and strategies for maximizing the potential of professional 3D printers, enabling businesses to stay competitive in an evolving marketplace.

Table of Contents

[Hide]

Understanding the Basics of Workflow Optimization in 3D Printing

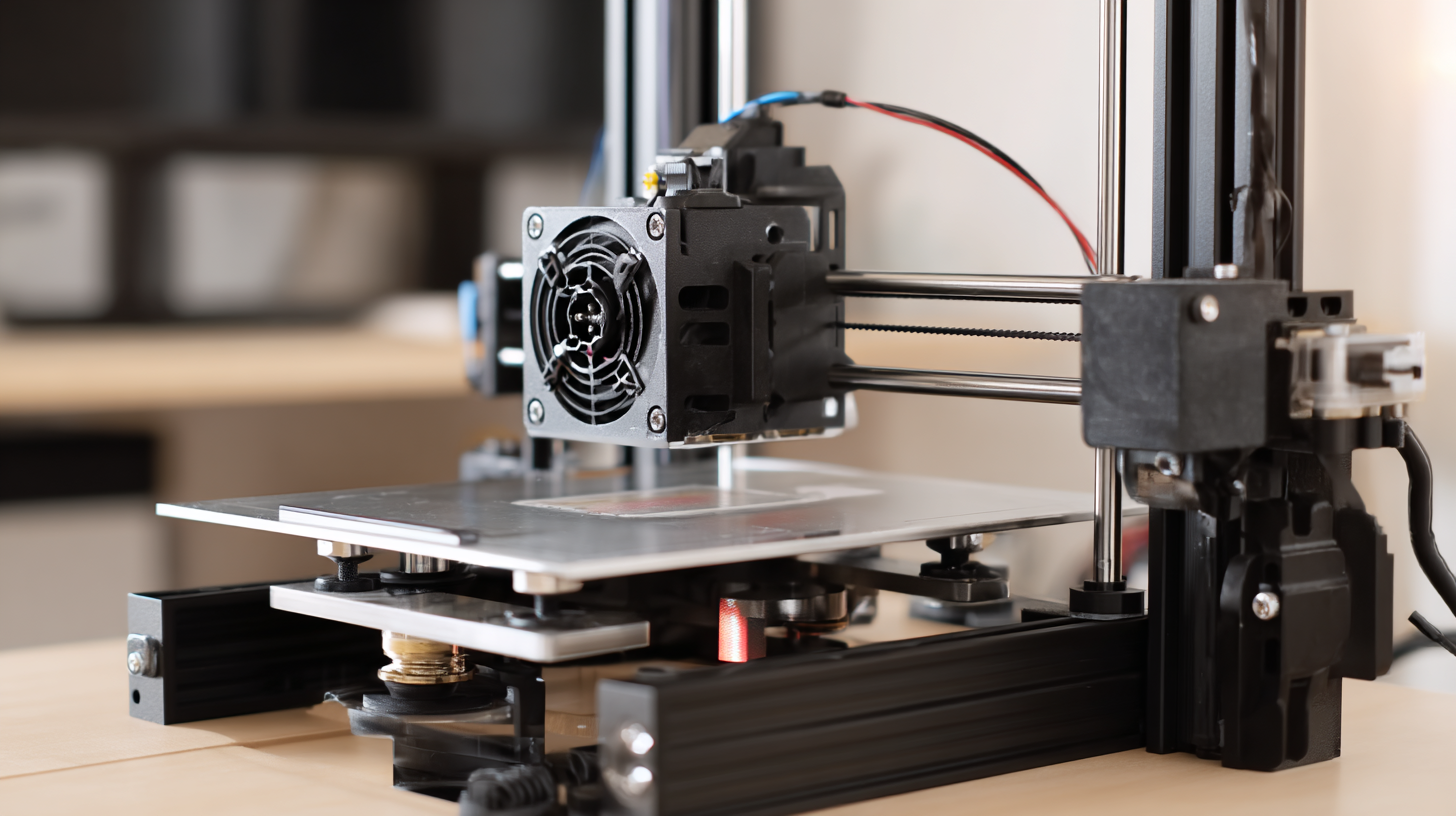

In the realm of 3D printing, optimizing your workflow can significantly enhance productivity and efficiency. Understanding the key elements of workflow optimization is essential for both new and experienced users. It involves assessing the entire 3D printing process, starting from the design phase to the final post-processing of the printed part. A streamlined workflow not only saves time but also reduces material waste and lowers costs.

**Tip**: Implement a standardized design process. By creating templates for common designs, you can reduce the time it takes to move from concept to print. This consistency is crucial for maintaining quality and efficiency throughout the production cycle.

Another vital aspect is effective project management. Keep track of all projects and their timelines to avoid bottlenecks. Utilizing project management tools specifically tailored for 3D printing can help coordinate steps more effectively, ensuring that each phase flows seamlessly into the next.

**Tip**: Invest in software that integrates well with your 3D printer. This can enhance the overall efficiency of your workflow, from slicing models to monitoring print jobs remotely, enabling you to make adjustments and maximize uptime.

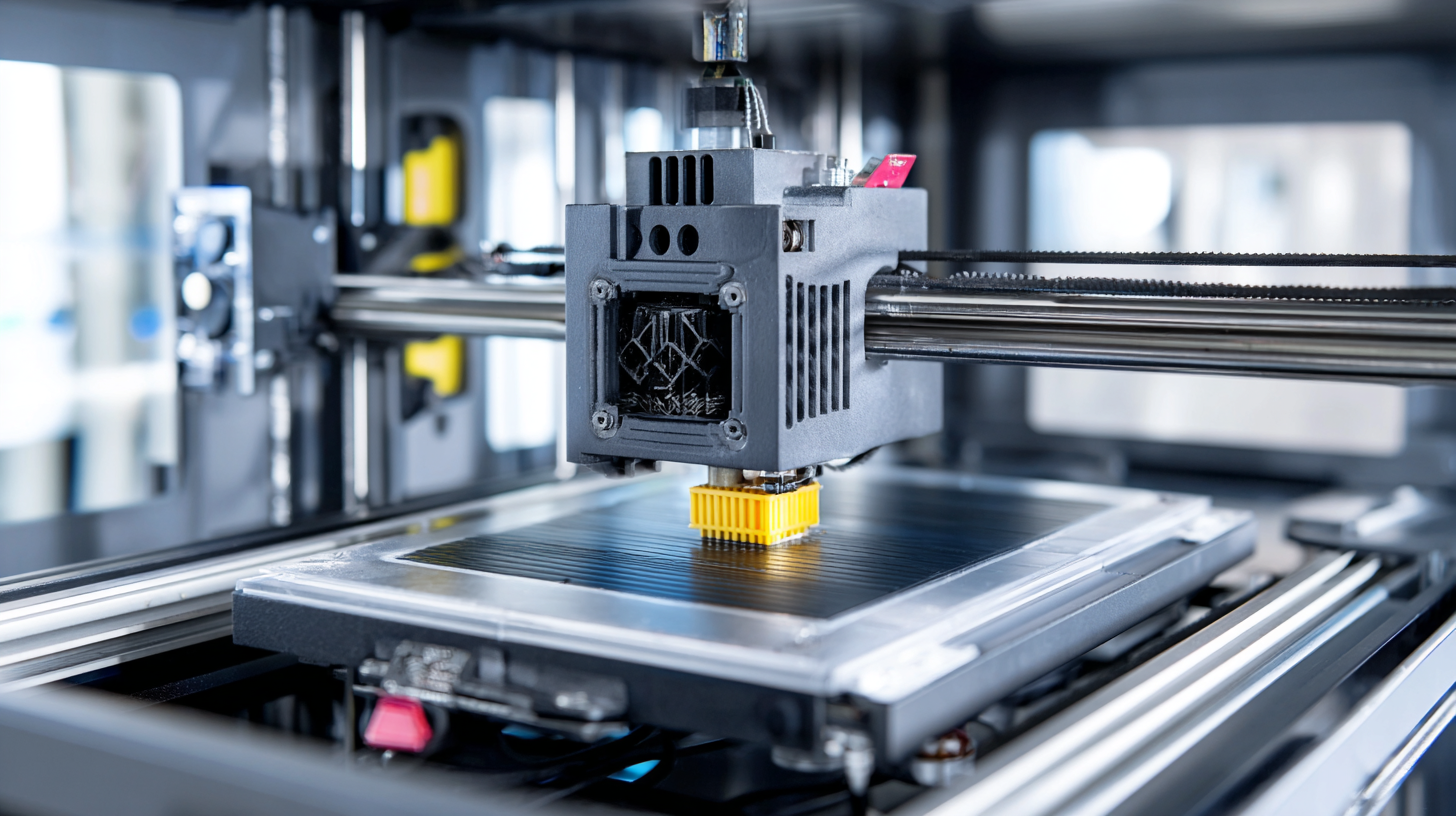

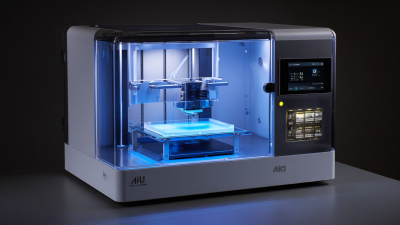

Choosing the Right 3D Printer for Your Specific Workflow Needs

Choosing the right 3D printer for your specific workflow needs is crucial for maximizing efficiency and output quality. Different industries and applications demand varied capabilities, such as speed, resolution, and material compatibility. For instance, a design studio focusing on prototyping may require a printer with high precision and the ability to work with multiple materials, while a manufacturing facility might prioritize speed and scalability. Evaluating these specific requirements against the features of available printers can streamline the selection process and enhance productivity.

It's also essential to consider the software ecosystem that accompanies your 3D printer. A user-friendly interface, compatibility with existing design tools, and robust support for slicing and file management can significantly influence your workflow efficiency. Engaging with industry experts and reading reviews can provide insights into how specific printers perform in real-world applications, helping you make informed decisions. By aligning the capabilities of your 3D printer with your operational needs, you can create a seamless integration that enhances your overall workflow.

How to Optimize Your Workflow with a Professional 3D Printer: Insights from Industry Experts

| 3D Printer Type | Printing Technology | Build Volume (mm) | Layer Height (µm) | Material Compatibility | Ideal Industry |

|---|---|---|---|---|---|

| FDM Printer | Fused Deposition Modeling | 250 x 250 x 250 | 100 - 400 | PLA, ABS, PETG | Prototyping, Education |

| SLA Printer | Stereolithography | 192 x 120 x 300 | 25 - 200 | Resins | Jewelry, Dental |

| SLS Printer | Selective Laser Sintering | 250 x 250 x 300 | 50 - 150 | Nylon, TPU | Automotive, Aerospace |

| DLP Printer | Digital Light Processing | 120 x 68 x 155 | 50 - 300 | Stereolithography Resin | Prototyping, Arts |

Implementing Efficient Design Processes for 3D Printing Projects

The 3D printing industry is experiencing a transformative shift as professionals increasingly adopt efficient design processes tailored for additive manufacturing. A recent industry analysis indicates that the global market for additive manufacturing materials is anticipated to grow significantly, projecting a compound annual growth rate (CAGR) of 20.1% from 2023, reaching $9.26 billion by 2030. This growth is attributed to the technology's ability to create customized structures with reduced material waste and shortened production times, which are paramount in today's fast-paced manufacturing landscape.

For instance, the ability to print complex designs with precise specifications has enabled businesses to overhaul traditional manufacturing approaches, leading to enhanced product quality and reduced costs. As organizations increasingly utilize advanced software for 3D modeling and design, the integration of AI technologies is also paving the way for new innovations, allowing for greater design freedom and efficiency. Moreover, projects such as those employing concrete 3D printing showcase the capability of this technology to revolutionize construction processes, indicating a broader trend toward optimizing workflows across various sectors through 3D printing solutions.

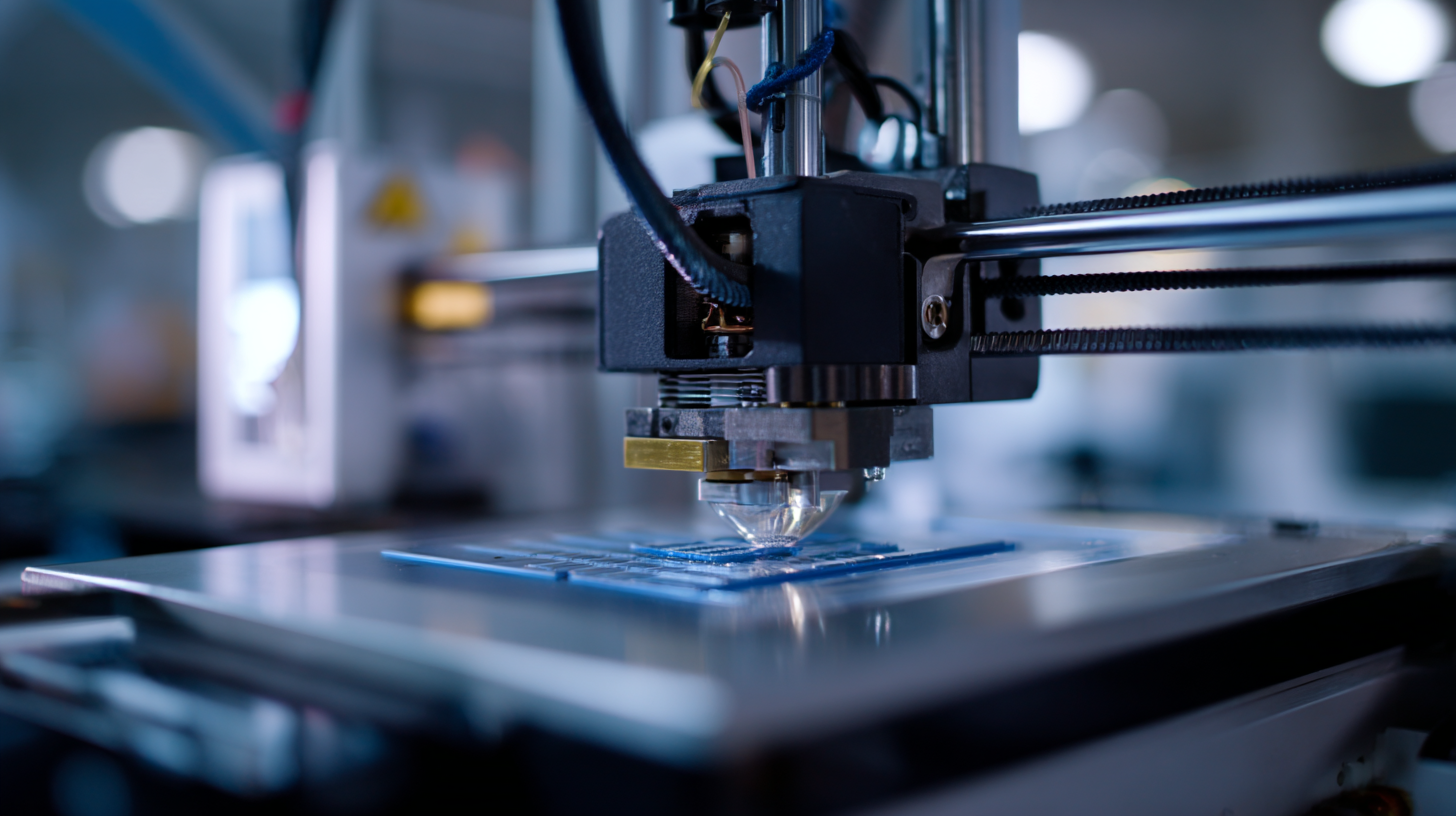

Integrating Software Solutions for Streamlined 3D Printing Workflows

Integrating software solutions into your 3D printing workflow is essential for maximizing efficiency and precision. Advanced software applications can streamline the entire process from design to production. For instance, utilizing CAD programs that are compatible with specific 3D printer models enables seamless export of designs that are ready for printing.

Moreover, these software solutions often include simulation features that allow designers to test their models virtually, minimizing errors before the physical printing begins.

Furthermore, many industry experts recommend implementing slicing software that optimally prepares the 3D model for printing. This software determines the best layer heights, infill patterns, and support structures, reducing material waste and printing time. Integrating cloud-based platforms can also enhance collaboration among team members, allowing remote access to designs and project updates in real-time.

By leveraging these software tools, businesses can ensure that their 3D printing operations not only run smoothly but also deliver high-quality results consistently.

Best Practices for Post-Processing and Finishing 3D Printed Parts

Post-processing and finishing are critical steps in the 3D printing process that can significantly enhance the quality and functionality of printed parts. According to a report by Wohlers Associates, over 40% of 3D printing enterprises invest in post-processing solutions to improve product performance and aesthetics. Techniques such as sanding, polishing, and chemical smoothing can eliminate layer lines and imperfections, resulting in parts that meet higher standards for professional applications.

Tips: When choosing a post-processing method, consider the material of your printed part. For instance, thermoplastics often benefit from acetone vapor smoothing, which can create a glossy finish and improve strength. Additionally, adopting a systematic approach to finishing can save time; integrating post-processing into your workflow ensures that it becomes an integral part of your production rather than an afterthought.

Furthermore, effective finishing can enhance the durability and appearance of parts, making them more suitable for end-use applications. A study by MIT revealed that parts subjected to advanced finishing techniques showed a 30% increase in overall mechanical properties. By investing time and resources in post-processing, companies can achieve a competitive edge in the market with superior products that stand out in both quality and performance.

Related Posts

-

The Future of Creative Production with 3D Plastic Printers

-

Top Strategies for Maximizing Efficiency with Sintering 3D Printers

-

Mastering the Basics of Powder 3D Printing with Our Step by Step Guide

-

Unlocking the Future Best 8K 3D Printer for Global Buyers

-

How to Choose the Right SLS Printer for Your Business: A Data-Driven Guide

-

5 Reasons Why Desktop SLS Printers Are Revolutionizing Small Scale Manufacturing