Top 5 SLS Printers for Exceptional 3D Printing in 2023: Buyers' Guide

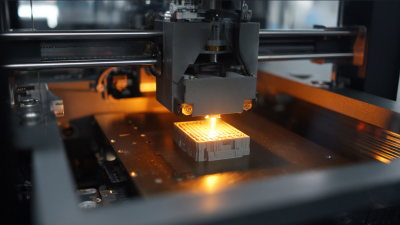

In the rapidly evolving landscape of additive manufacturing, Selective Laser Sintering (SLS) has emerged as a cornerstone technology for producing high-quality 3D printed parts. As we delve into the top SLS printers for 2023, it is essential to consider not only the technological advancements but also the market trends shaping this industry. According to the latest report by SmarTech Analysis, the SLS 3D printing market is projected to grow from $1.1 billion in 2022 to over $2.5 billion by 2025, propelled by increasing demand for customized production and engineering-grade materials.

Industry expert Dr. Emily Rosen, a leading figure in 3D printing technology, emphasizes the importance of choosing the right SLS printer: "The right equipment can significantly enhance production efficiency and part quality, making it essential for businesses to stay ahead in a competitive market." With innovations in technology and materials, today's SLS printers offer unparalleled precision, versatility, and speed, catering to a wide range of applications from aerospace to medical devices.

As we explore the top contenders in the SLS printer market for 2023, this buyer's guide aims to equip you with the insights needed to make informed decisions in your investment strategy. Whether you are a seasoned professional or a newcomer to the field, understanding the capabilities and features of these advanced machines is crucial for achieving exceptional results in your 3D printing endeavors.

Table of Contents

[Hide]

Top Features to Look for in SLS Printers for Optimal Performance

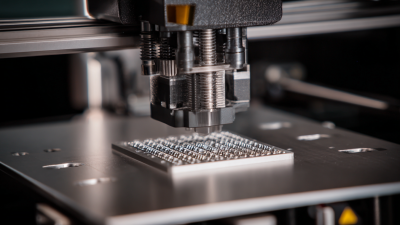

When selecting an SLS printer for optimal performance in 2023, several key features should be prioritized to ensure that your investment meets both current and future demands. Notably, the build volume is a critical factor; printers with larger build volumes can produce bigger parts or more components per cycle, significantly enhancing productivity. According to a recent industry report by MarketsandMarkets, the SLS 3D printing market is projected to reach $1.5 billion by 2025, reflecting the growing need for larger and more efficient machines.

Another essential feature to consider is the precision and layer resolution of the printer. High-resolution printers provide better detail and finer surface finishes, which are crucial for industries such as aerospace and medical device manufacturing, where precision is paramount. A study from Wohlers Associates indicated that the accuracy of SLS prints has improved by over 30% in the last five years, making high-quality printers indispensable for professional applications.

Additionally, look for advanced thermal management systems that ensure consistent part quality by maintaining optimal temperatures during the printing process. This innovation not only reduces the risk of warping but also plays a role in improving the mechanical properties of the final product. As indicated in Statista reports, automated features are also gaining traction, with over 50% of manufacturers now preferring printers with automated loading and unloading systems to streamline their workflow.

Comparative Analysis of the Best SLS Printers in 2023

When exploring the market for SLS printers in 2023, a comparative analysis reveals a variety of outstanding models suited for different needs. Each printer stands out due to unique features, build volume, print quality, and overall user experience. For instance, some models excel at rapid prototyping, allowing designers to iterate quickly, while others may prioritize detailed precision at the expense of speed. Understanding these differences is crucial for making an informed decision.

Tip: Before purchasing an SLS printer, consider your specific needs—whether it’s for industrial-scale production or small batch runs—since these factors significantly influence the choice of equipment. Additionally, look into customer reviews and case studies to gauge real-world performance and reliability.

Moreover, pricing is an essential aspect to consider alongside the technical specifications. High-end models might come with advanced features, but there are also budget-friendly options that deliver impressive results. Balancing performance with cost can help you find a printer that not only fits your budget but also meets your printing requirements effectively.

Top 5 SLS Printers for Exceptional 3D Printing in 2023

| Model | Build Volume (mm) | Layer Thickness (μm) | Speed (cm³/h) | Material Compatibility | Price (USD) |

|---|---|---|---|---|---|

| SLS Printer A | 300 x 300 x 300 | 100 | 15 | Nylon, TPU | 5,000 |

| SLS Printer B | 250 x 250 x 280 | 80 | 20 | Nylon, PLA | 6,500 |

| SLS Printer C | 200 x 200 x 250 | 120 | 10 | Nylon, PETG | 4,500 |

| SLS Printer D | 350 x 350 x 400 | 90 | 25 | Nylon, PC | 8,000 |

| SLS Printer E | 300 x 300 x 300 | 75 | 18 | Nylon, TPU | 7,200 |

User Experience: Real-Life Reviews of Leading SLS Printers

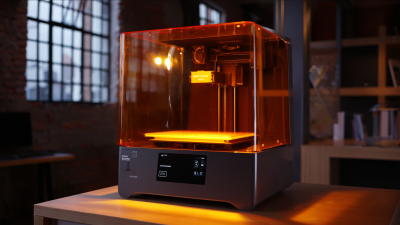

In the competitive landscape of 3D printing, selective laser sintering (SLS) technology stands out for its ability to produce intricate, durable parts with exceptional surface finishes. User experiences reveal a spectrum of opinions on various SLS printers available in 2023. According to a report by SmarTech Analysis, the global SLS 3D printer market is projected to grow at a CAGR of 20% through 2026, driven by increasing demand in industries such as aerospace, automotive, and healthcare. Many users have praised leading models for their reliability and efficiency, noting that print quality significantly impacts end-product applications.

Real-life reviews from professionals highlight printers like the EOS P 500 for its large build volume and advanced thermal management, making it ideal for production-scale needs. In contrast, the Formlabs Fuse 1 has garnered attention for its user-friendly interface and cost-effectiveness, particularly for small to medium enterprises venturing into industrial-grade 3D printing. Users in various sectors report decreased production time and lower overhead costs, thereby reinforcing the value proposition of investing in high-quality SLS printers. As the technology continues to evolve, end-users will inevitably demand greater performance and versatility, further shaping the future of 3D printing.

Top 5 SLS Printers Performance Comparison

Cost-Benefit Breakdown: Is Investing in an SLS Printer Worth It?

When considering the investment in an SLS (Selective Laser Sintering) printer, it's essential to weigh the cost against the potential benefits. SLS printers can produce high-quality, intricate designs with exceptional strength and durability, making them ideal for industries such as aerospace, automotive, and medical. However, the initial cost of these machines can be significant, typically ranging from a few thousand to several hundred thousand dollars. Therefore, understanding your specific needs and how frequently you'll use the printer is crucial.

Tips: Assess your budget and consider the total cost of ownership, including maintenance, materials, and operational costs. If you plan to use the printer regularly for prototyping or production, an SLS printer can save you time and money in the long run by reducing dependency on outsourcing. Additionally, keep an eye out for software and training costs that may arise, as these can impact your overall investment.

The technology's ability to create highly customized parts quickly can lead to substantial savings for companies with innovative designs. However, for smaller businesses or those with infrequent printing needs, alternative printing technologies like FDM or SLA may provide a more cost-effective solution. Carefully evaluating your requirements will enable you to make an informed decision on whether an SLS printer is worth the investment.

Maintenance Tips for Prolonging the Life of Your SLS Printer

Maintaining your SLS printer is crucial for ensuring its longevity and optimal performance. Regular maintenance routines should include cleaning the chamber and build platform after every use, as leftover powder can adversely affect future prints. Utilizing a vacuum or a gentle brush helps in removing residual materials without damaging sensitive components. Additionally, it is essential to inspect and replace parts, such as lasers and lenses, according to the manufacturer's recommendations to avoid costly downtime.

Another important aspect of maintenance is monitoring the printer's software and firmware updates. Keeping the software up to date enhances stability and introduces new features that can improve print quality. Furthermore, maintaining a controlled environment for your printer, including consistent temperature and humidity levels, can prevent warping and ensure even melting of the powder. By following these tips, you can prolong the life of your SLS printer and maintain its printing capabilities effectively.

Related Posts

-

What is the Future of 3D Printing Machines in Global Manufacturing

-

Why Laser Sintering 3D Printers Are Revolutionizing Manufacturing Efficiency by 30%?

-

Unlocking the Future of Creativity with 3D Printers for Every Home

-

Top 5 Laser Sintering 3D Printers You Need to Know for High Quality Prototyping

-

Challenges Faced by Businesses in Adopting Commercial 3D Printers

-

Exploring the Future of 3D Printing with DLP Resin Technology