The Ultimate Guide to Choosing the Best Desktop SLS Printer for Your 3D Printing Needs

As the demand for high-quality 3D printing continues to grow across various industries, selecting the right equipment becomes crucial for achieving optimal results. Among the various technologies available, the desktop SLS printer stands out for its ability to produce intricate and durable parts through selective laser sintering. According to a recent report by SmarTech Analysis, the market for SLS 3D printing is projected to reach $1.2 billion by 2025, highlighting the increasing adoption of this technology in sectors such as aerospace, automotive, and healthcare. However, with numerous options available, choosing the best desktop SLS printer requires careful consideration of factors such as build volume, material compatibility, and user-friendliness. This guide aims to provide valuable insights and expert recommendations to help you navigate the complexities of selecting a desktop SLS printer that meets your specific 3D printing needs.

Table of Contents

[Hide]

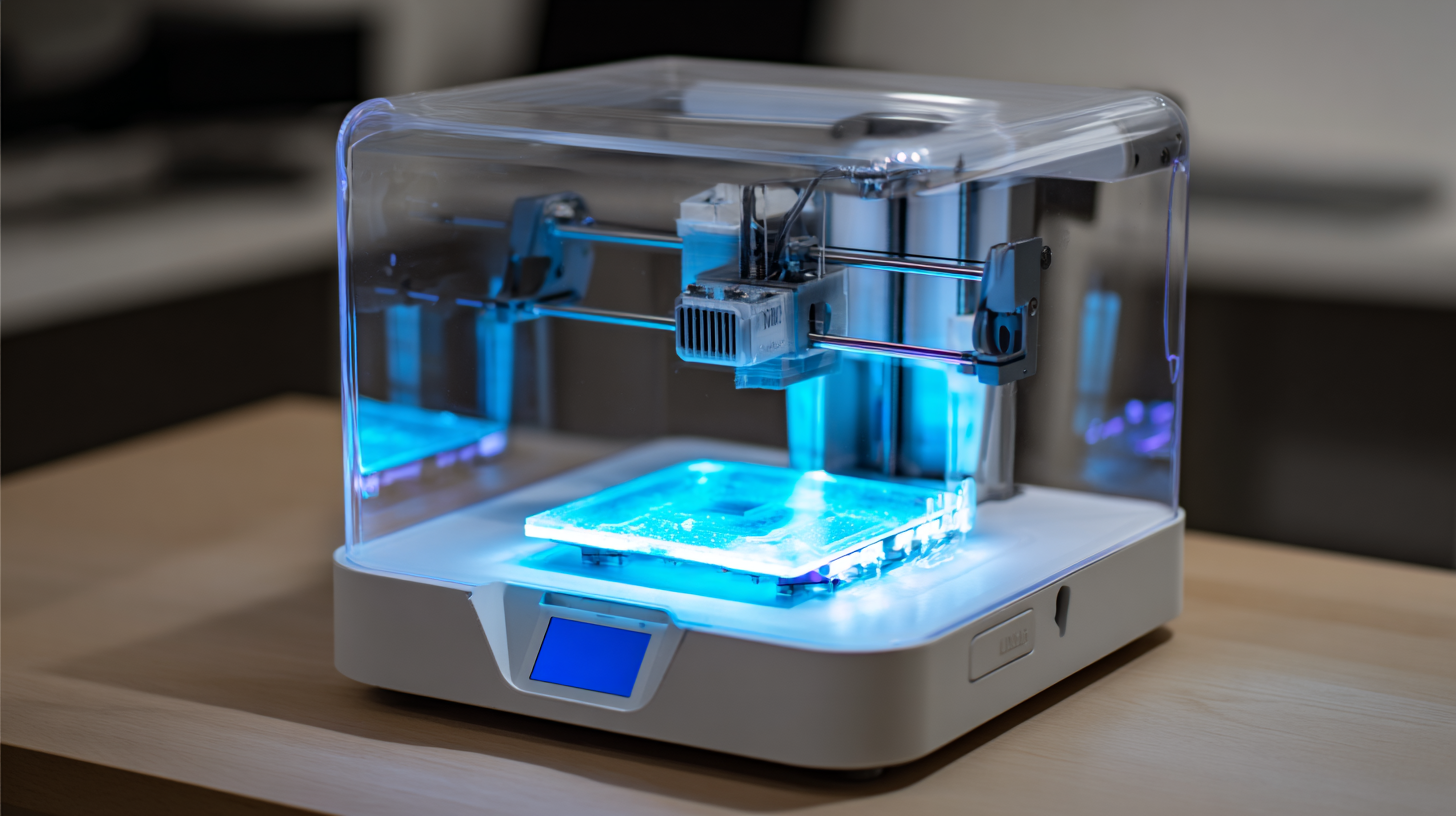

Understanding SLS Technology and Its Advantages for 3D Printing

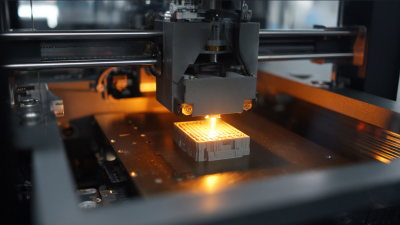

Selective Laser Sintering (SLS) technology has emerged as a game-changer in the realm of 3D printing, particularly when it comes to producing high-quality, functional parts. The key advantage SLS holds over other additive manufacturing techniques is its ability to create complex geometries without the need for support structures, enabling the production of lightweight yet durable components. Recent market analysis indicates that the SLS 3D printing market was valued at approximately $1.353 billion in 2023, projected to reach $2.812 billion by 2032, reflecting a robust compound annual growth rate of 8.5%. This growth is driven by the demand for efficient production methods and the ability to customize parts on demand.

Before diving into SLS printing, it is essential to evaluate specific requirements such as part types, production quantities, lead times, and performance specifications. Cost-effective batch production is becoming more achievable as SLS technology continues to refine its process. With insight from industry reports, we understand that the processing costs have decreased significantly, with nylon material costs dropping below $1 per gram, which fosters greater accessibility for businesses aiming to leverage 3D printing for high-performance applications.

Key Factors to Consider When Choosing an SLS Desktop Printer

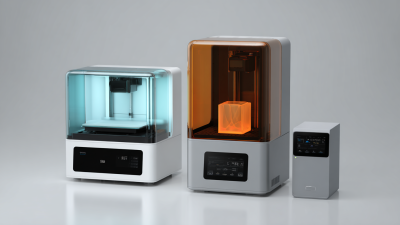

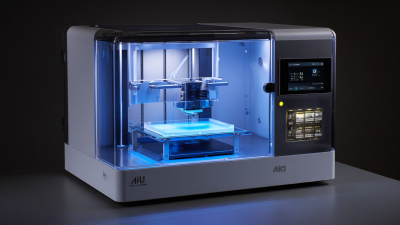

When selecting the best desktop SLS printer for your 3D printing needs, it's essential to consider several key factors. First, evaluate the build volume of the printer, as this will determine the size of the prints you can produce. A larger build volume is beneficial for creating bigger parts or multiple small items simultaneously. Look for printers that balance size with the overall footprint to fit in your workspace efficiently.

Another crucial aspect is the material compatibility of the printer. Different SLS printers support various types of materials, which can affect the strength, flexibility, and finish of your final product. Ensure the printer you choose can handle the materials that best suit your application needs, whether it be nylon, TPU, or composite filaments.

**Tips:** Always check for user reviews and case studies related to specific printers. These can provide insights into the printer's reliability and print quality. Additionally, consider the software offered with the printer; user-friendly interfaces can significantly enhance your printing experience and efficiency. Lastly, look into the after-sales support provided by the manufacturer, as good customer service can save you time and troubleshooting headaches later on.

The Ultimate Guide to Choosing the Best Desktop SLS Printer for Your 3D Printing Needs - Key Factors to Consider When Choosing an SLS Desktop Printer

| Feature | Importance | Recommended Value |

|---|---|---|

| Build Volume | High | Minimum 200 x 200 x 200 mm |

| Layer Thickness | Medium | 0.1 mm to 0.15 mm |

| Material Compatibility | High | Nylon, TPU, etc. |

| Print Speed | Medium | 15 to 30 mm/hr |

| User Interface | Medium | Touchscreen preferred |

| Maintenance Requirements | High | Regular cleaning, parts replacement |

| Price Range | High | $5,000 - $15,000 |

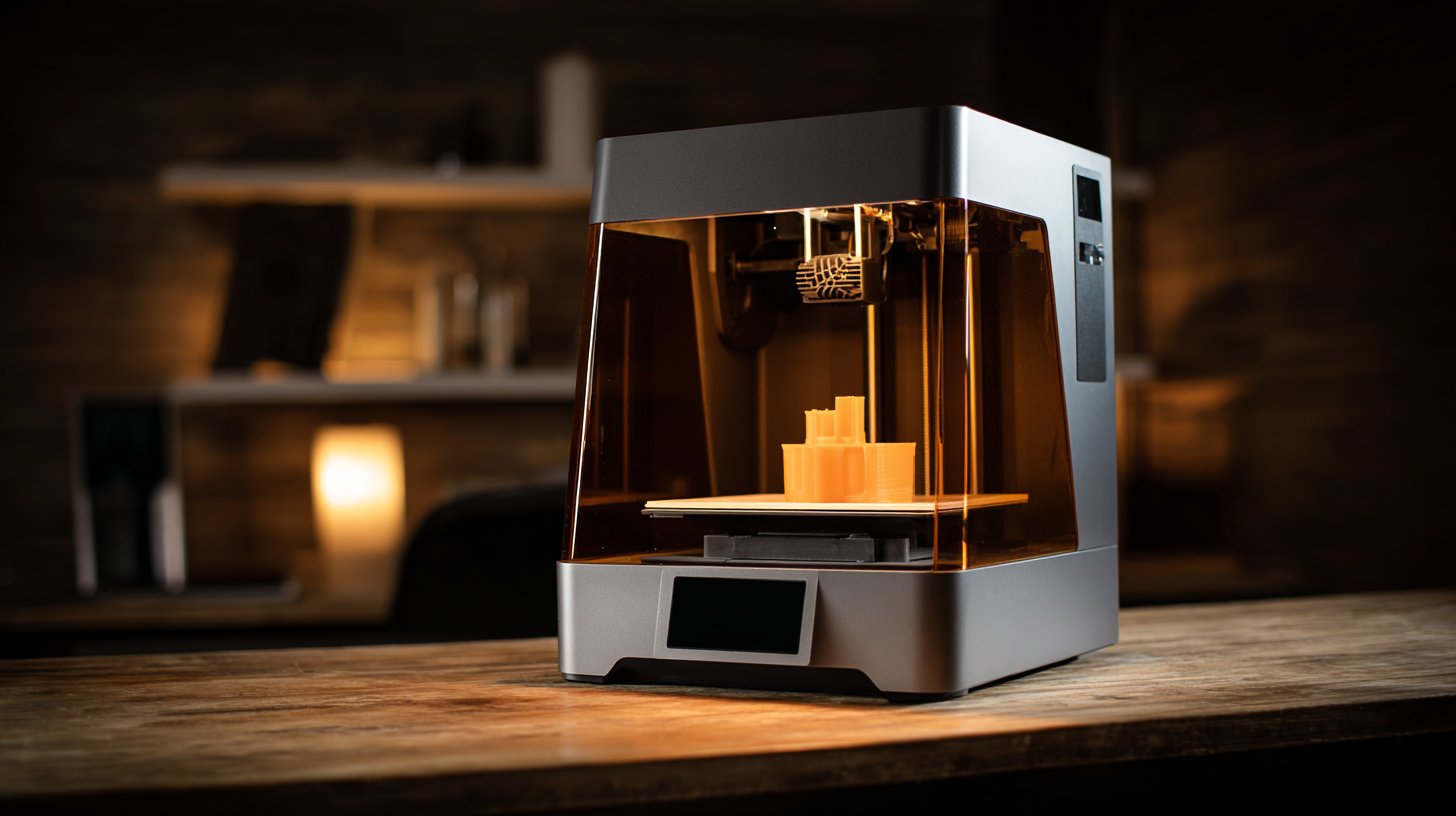

Top SLS Printers on the Market: Features and Comparisons

When considering a desktop SLS printer for your 3D printing needs, it's essential to evaluate the features of the models available on the market. The demand for polymer 3D printing has surged, with reports indicating a staggering 43.3% growth in polymer powder consumption in 2021. This spike underlines the importance of choosing a reliable SLS printer that meets diverse applications such as prototyping, model-making, and industrial production.

Leading SLS printers offer a variety of features that can significantly enhance the quality and efficiency of 3D printing projects. For instance, advancements in powder bed fusion technology allow for fine-tuning of layer thickness, resulting in smoother finishes and increased detail in prints. With many options tested in 2025, the industry's offerings range from affordable budget models to robust industrial machines tailored for high-end applications. Understanding these offerings and their specific capabilities can help you identify the best fit for your operational requirements, ensuring you stay ahead in the rapidly evolving 3D printing landscape.

The Performance Comparison of Desktop SLS Printers

Cost Analysis: Budgeting for Your SLS Printing Setup

When budgeting for an SLS printing setup, it's crucial to consider not only the initial costs of the printer itself but also the ongoing expenses associated with materials and maintenance. A detailed cost analysis can help you understand the total financial commitment required for a successful operation. The setup requirements may include workspace considerations, safety equipment, and operational tools, each contributing to the overall budget.

Emerging trends in 3D printing indicate a shift towards more affordable and versatile materials, making it increasingly feasible for newcomers to enter the market without extensive financial backing. Additionally, the landscape is rich with opportunities for customization, allowing businesses to cater to specific niches, such as biomanufacturing or prototyping, thereby justifying the investment in quality equipment. As you plan your setup, it's important to evaluate different printer models and material options that align with your budget while ensuring high efficiency and output quality.

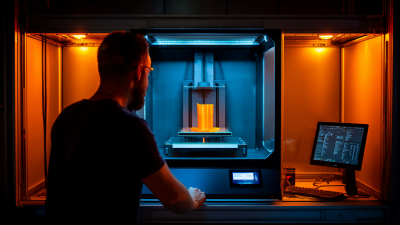

Maintenance and Support: Ensuring Long-Term Success with Your Printer

When investing in a desktop SLS printer, maintenance and support are crucial elements that can significantly affect your long-term success. Regular upkeep of your printer not only ensures optimal performance but also extends its lifespan. This includes routine cleaning, timely replacement of worn-out parts, and adhering to the manufacturer’s recommended maintenance schedules. Understanding the intricacies of your specific model can prevent costly repairs and the frustration of unexpected downtime.

Moreover, reliable customer support can make a significant difference in your SLS printing experience. Choose a manufacturer that offers comprehensive support services, including troubleshooting assistance and access to a resource center filled with tutorials and guides. A responsive support team can help you navigate any technical challenges, ensuring that you continue to produce high-quality prints. Investing time in establishing a relationship with your manufacturer’s support resources can create a strong foundation for ongoing success in your 3D printing endeavors.

Related Posts

-

How to Choose the Right SLS Printer for Your Business: A Data-Driven Guide

-

Why Laser Sintering 3D Printers Are Revolutionizing Manufacturing Efficiency by 30%?

-

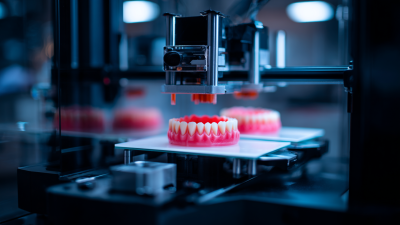

How to Choose the Right Dental 3D Printer for Your Practice Needs

-

Revolutionizing Oral Care: The Impact of Dental 3D Printers on Modern Dentistry

-

Top Strategies for Maximizing Efficiency with Sintering 3D Printers

-

Unlocking the Future Best 8K 3D Printer for Global Buyers